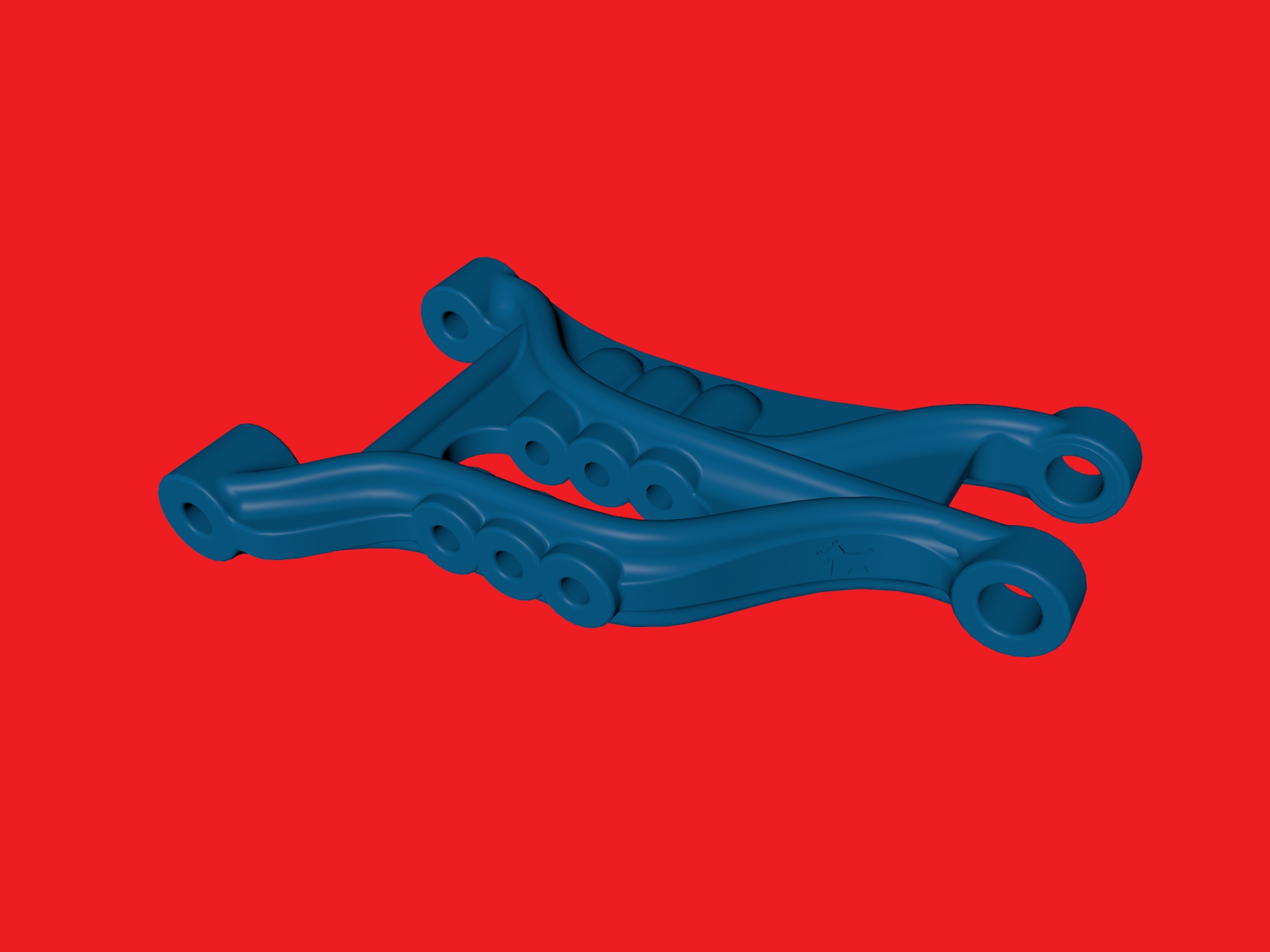

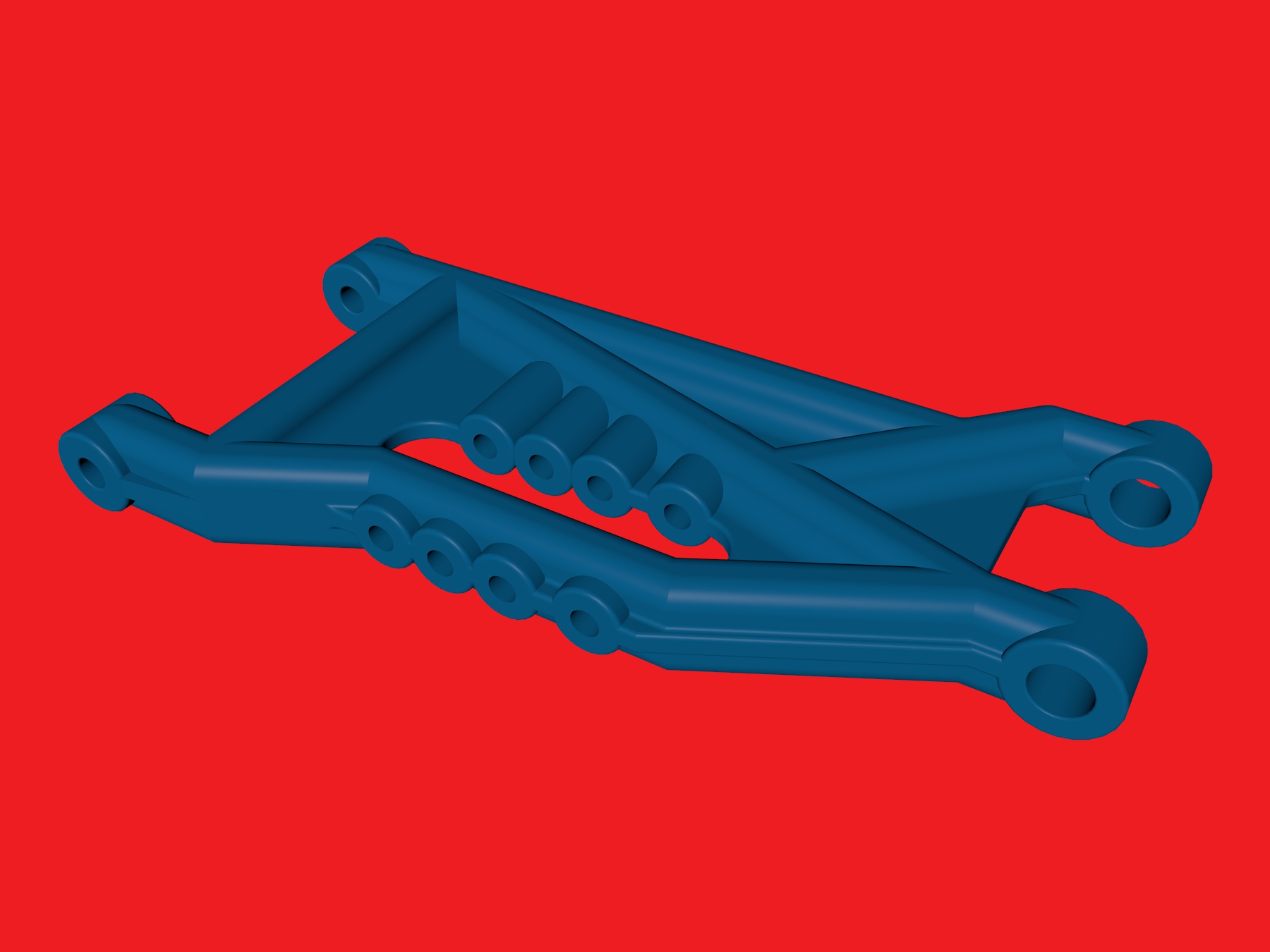

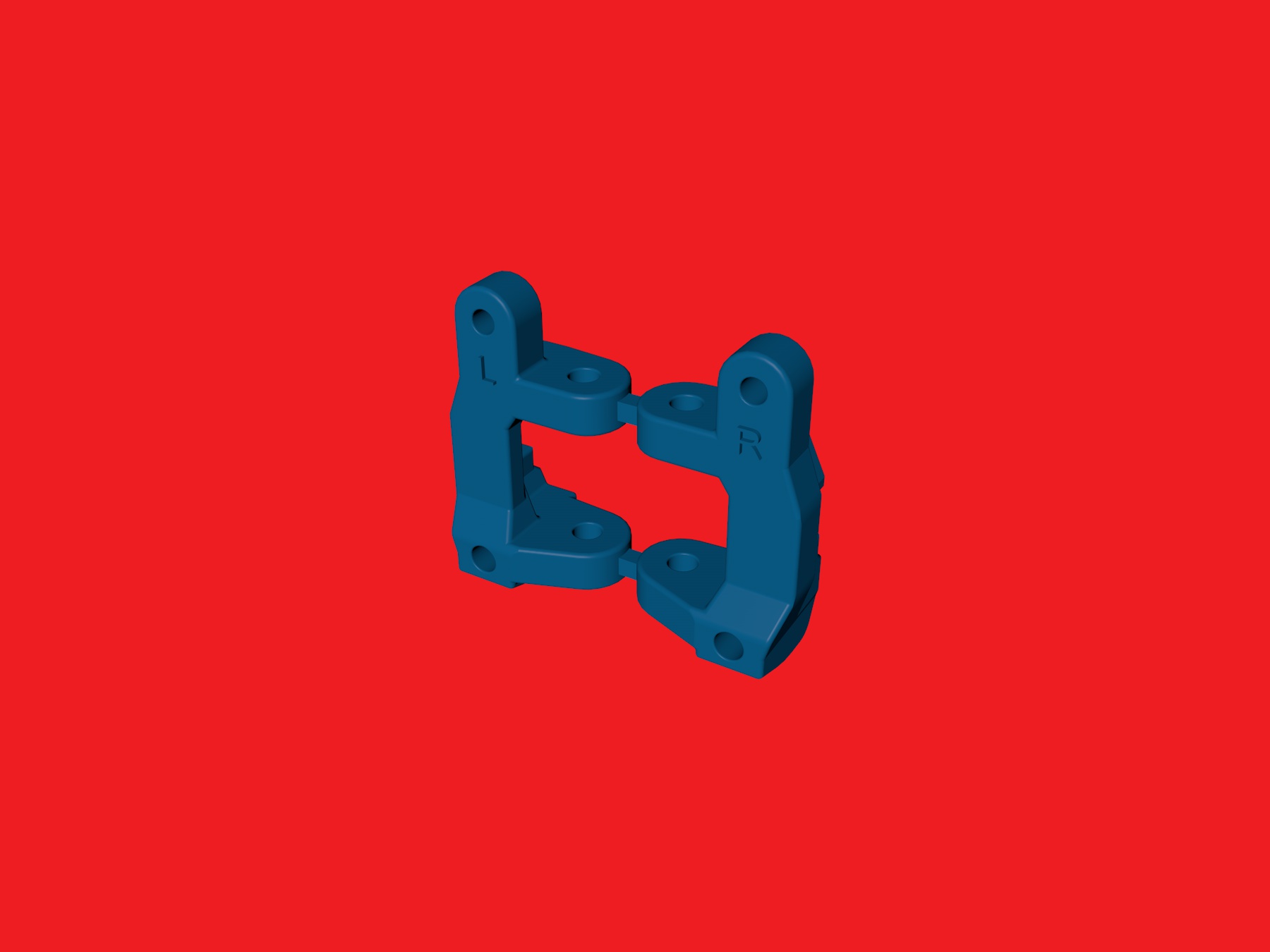

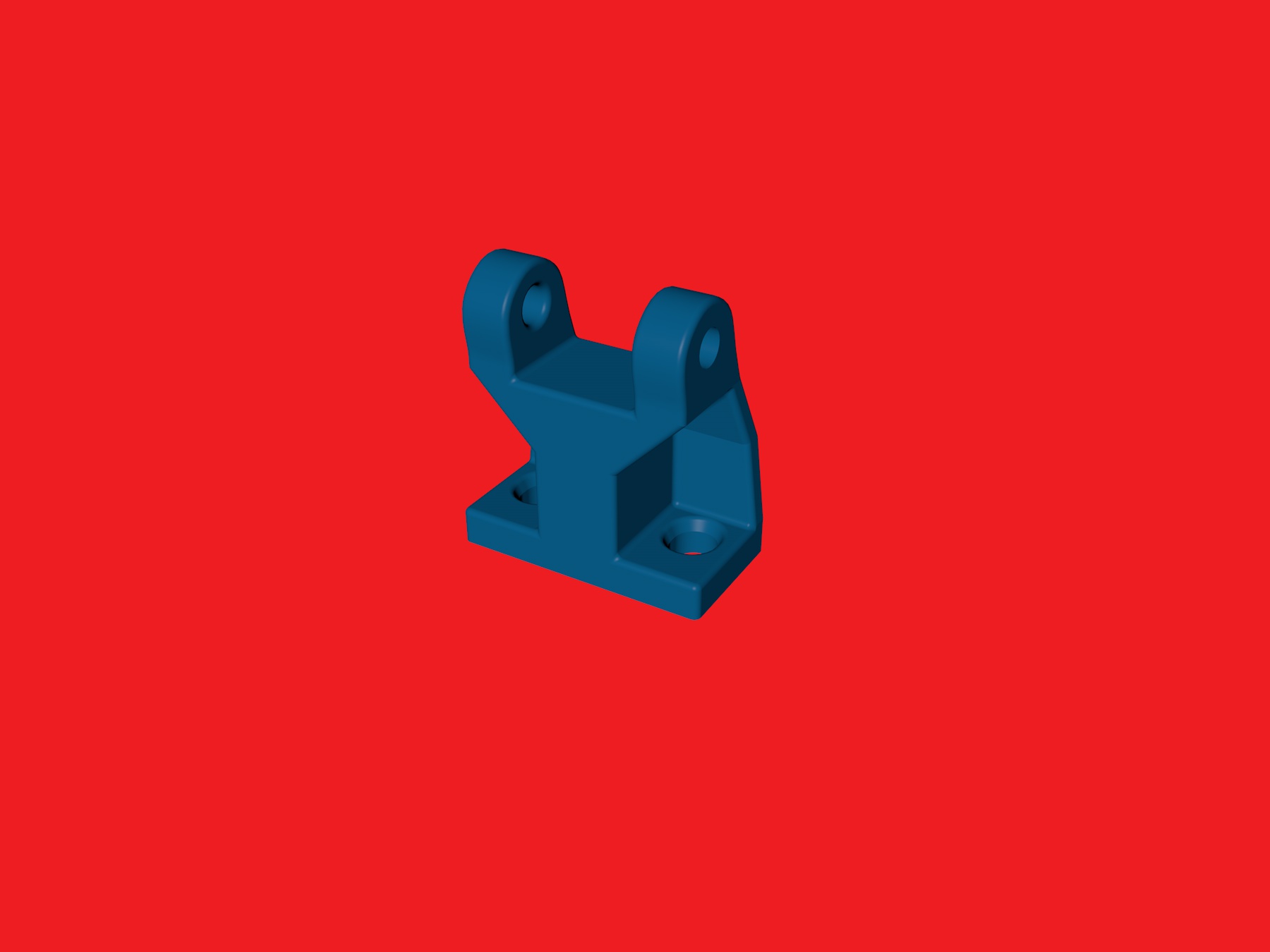

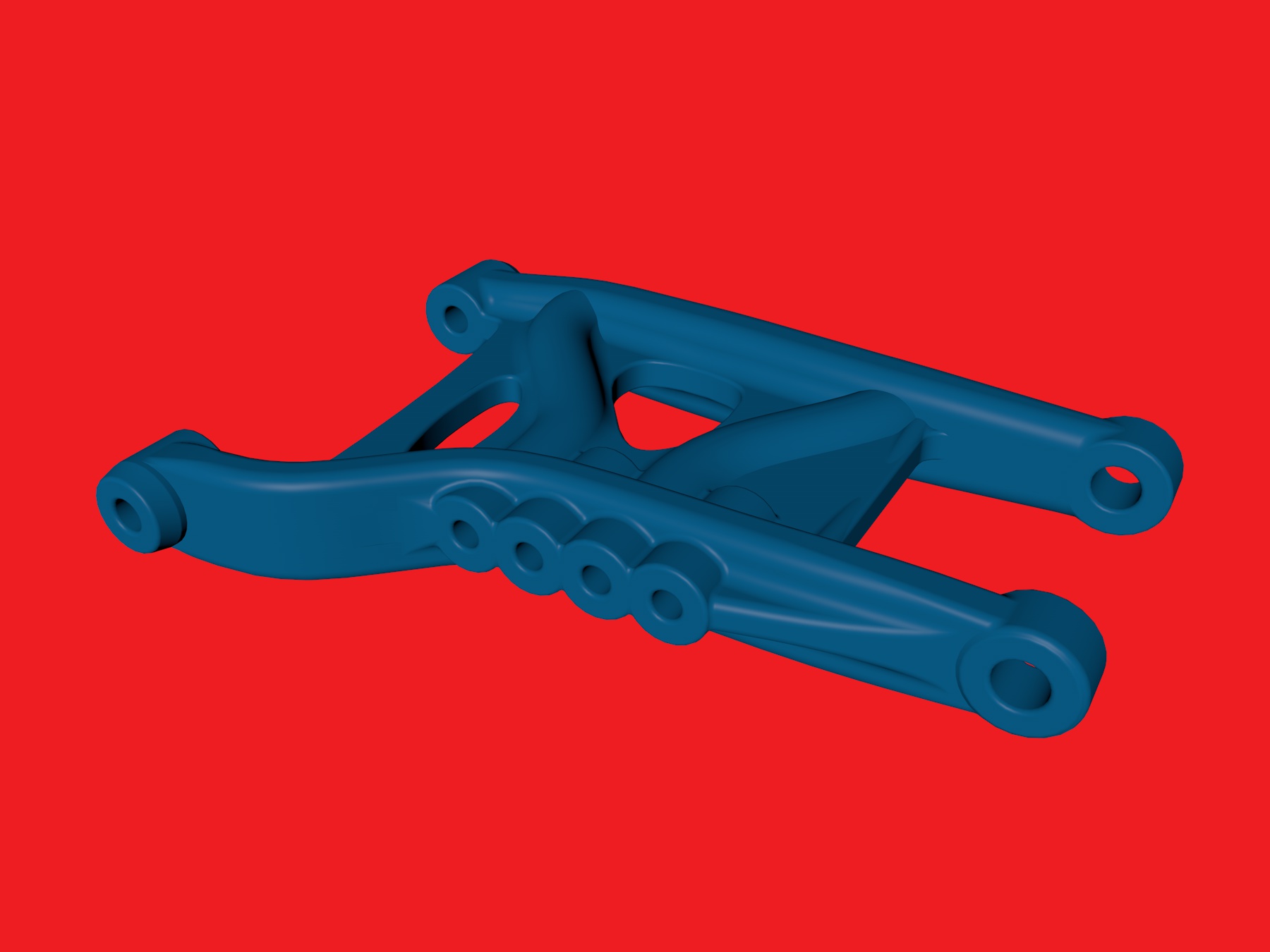

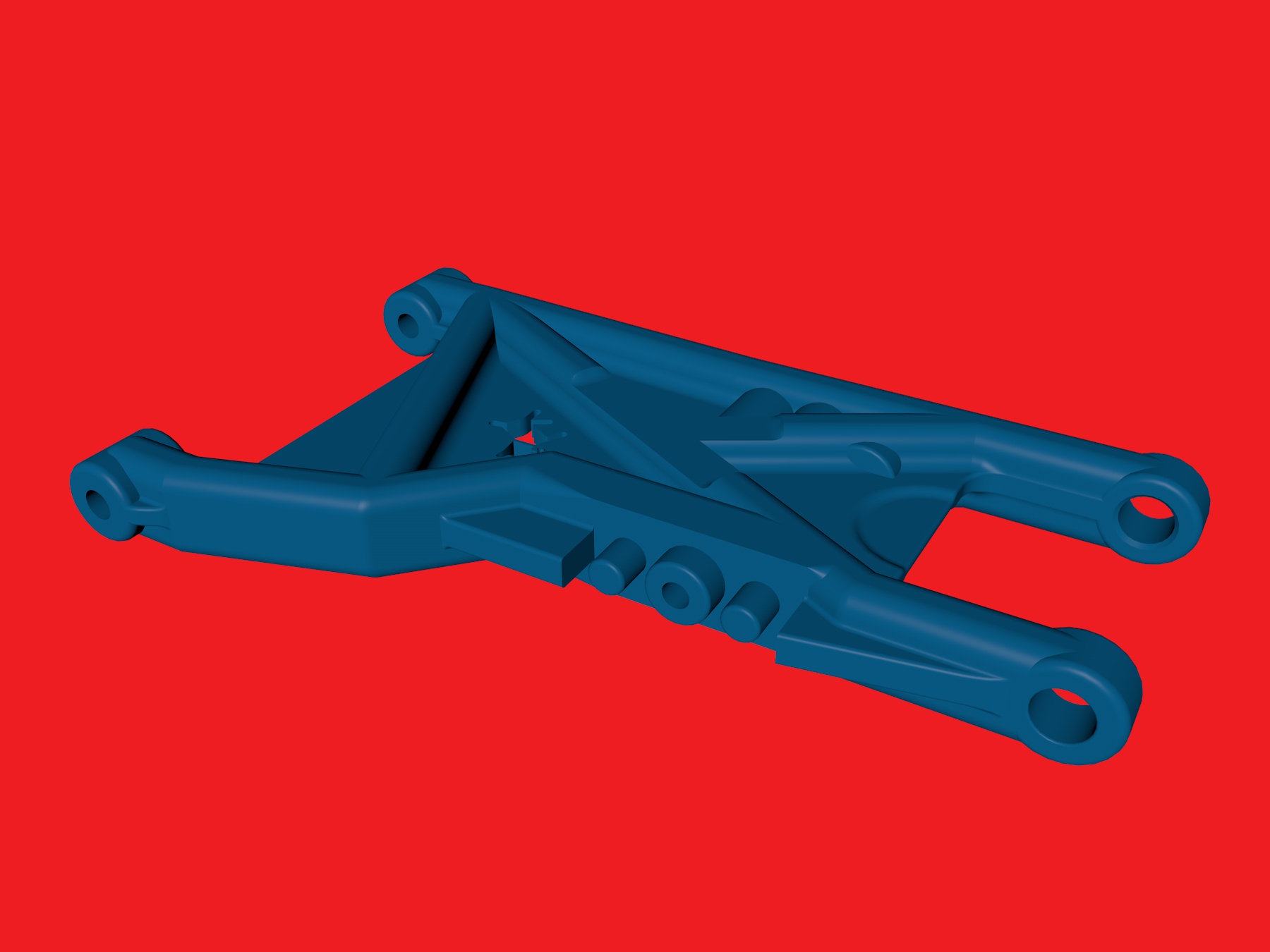

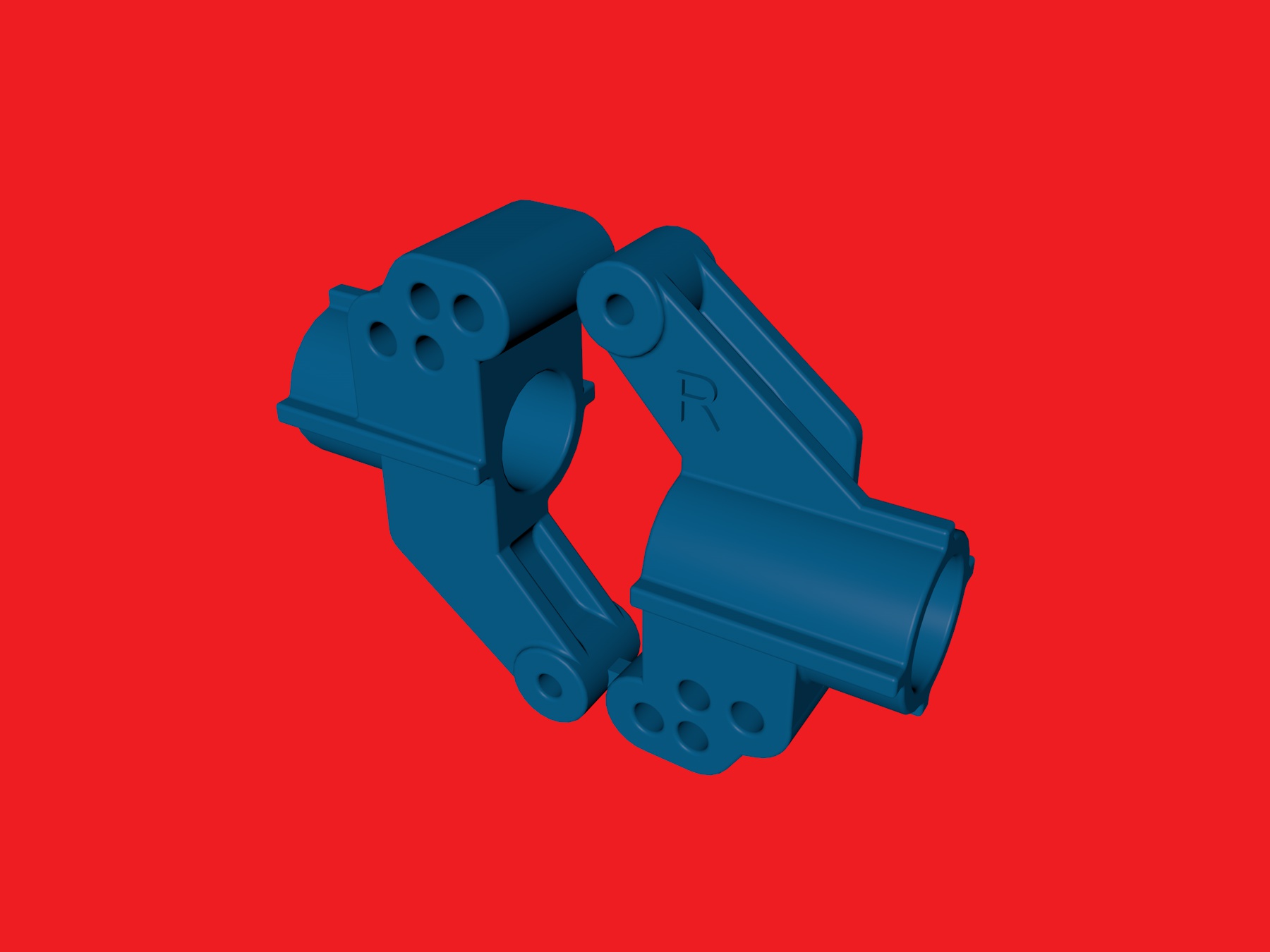

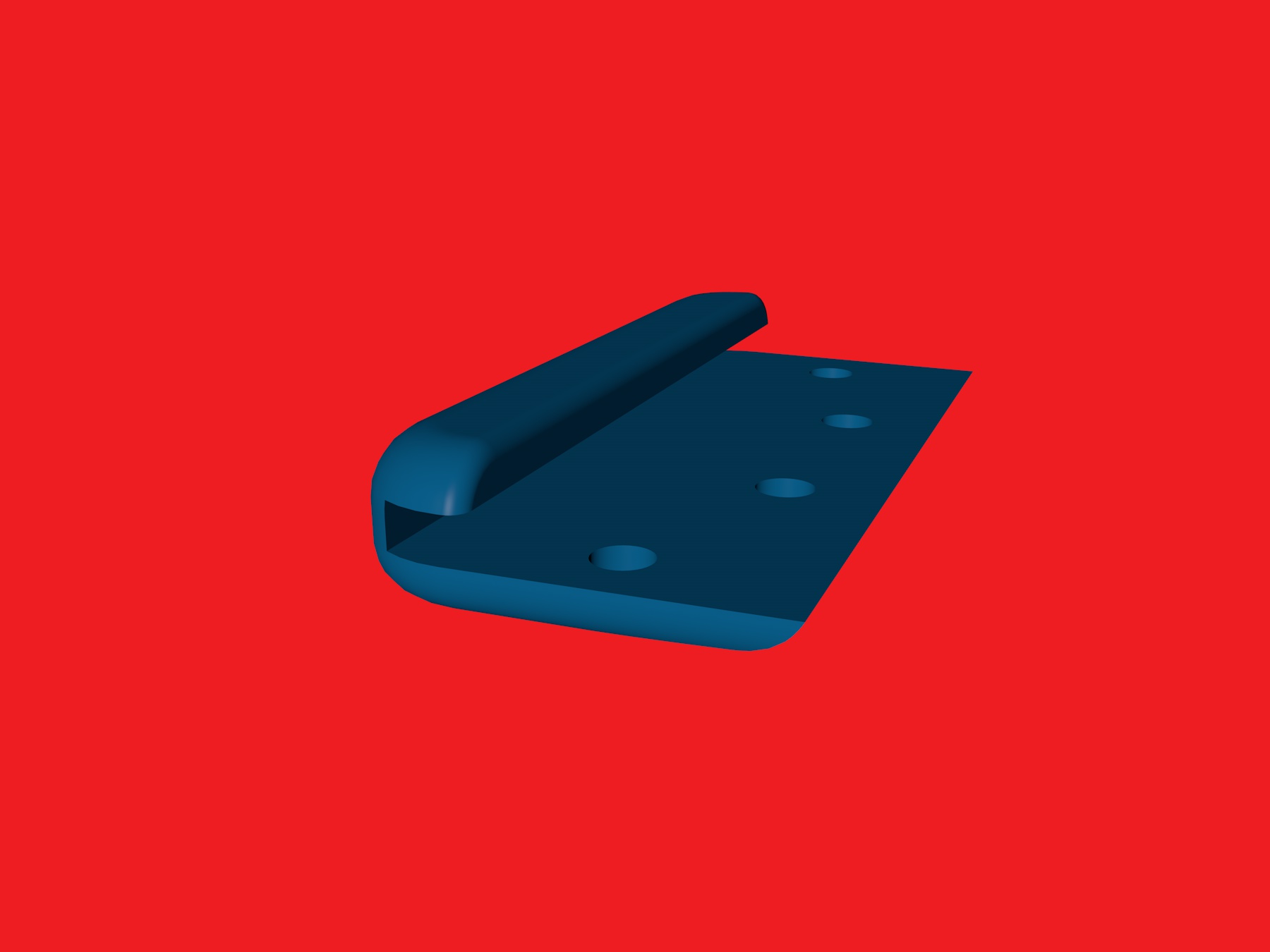

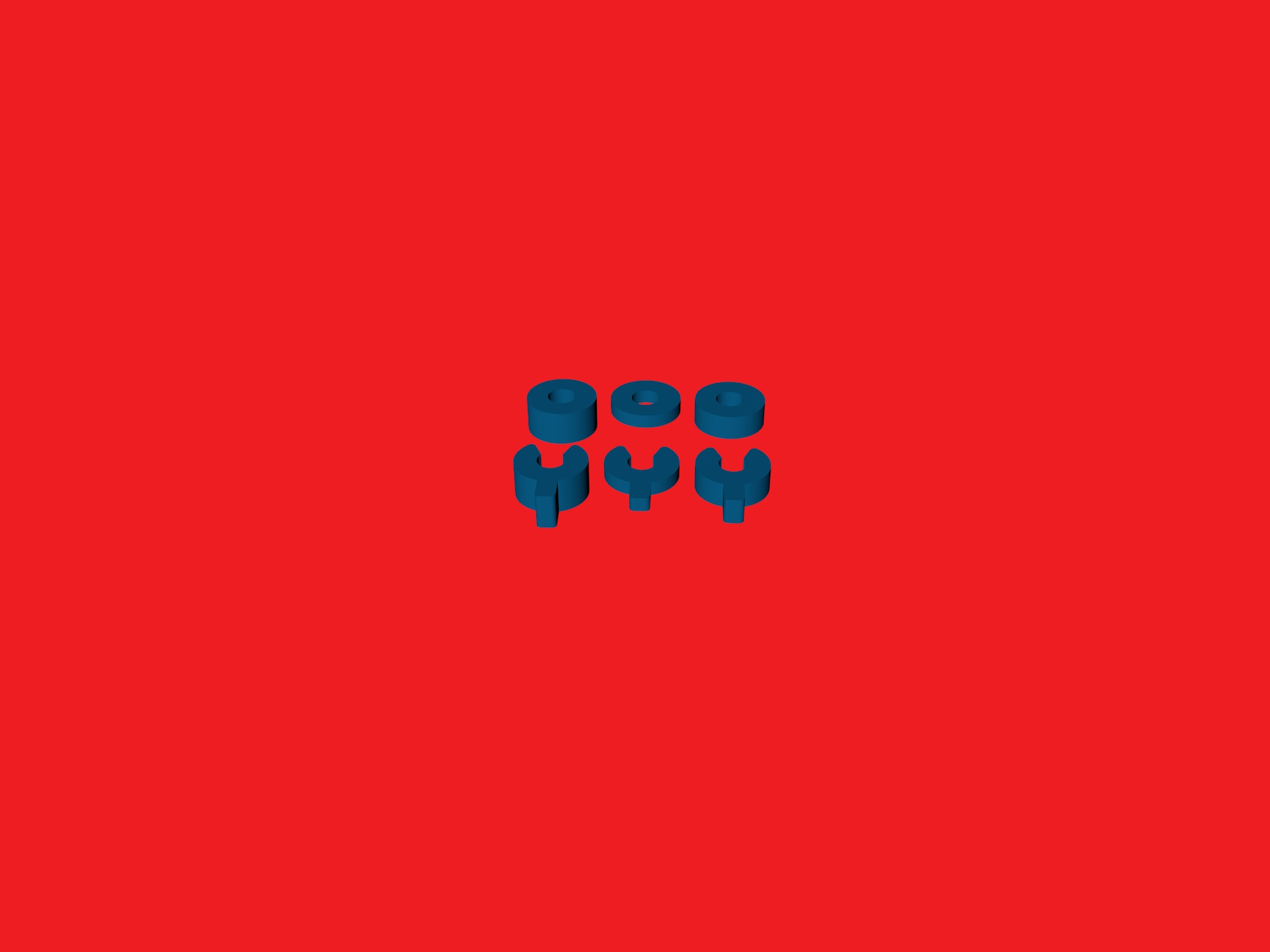

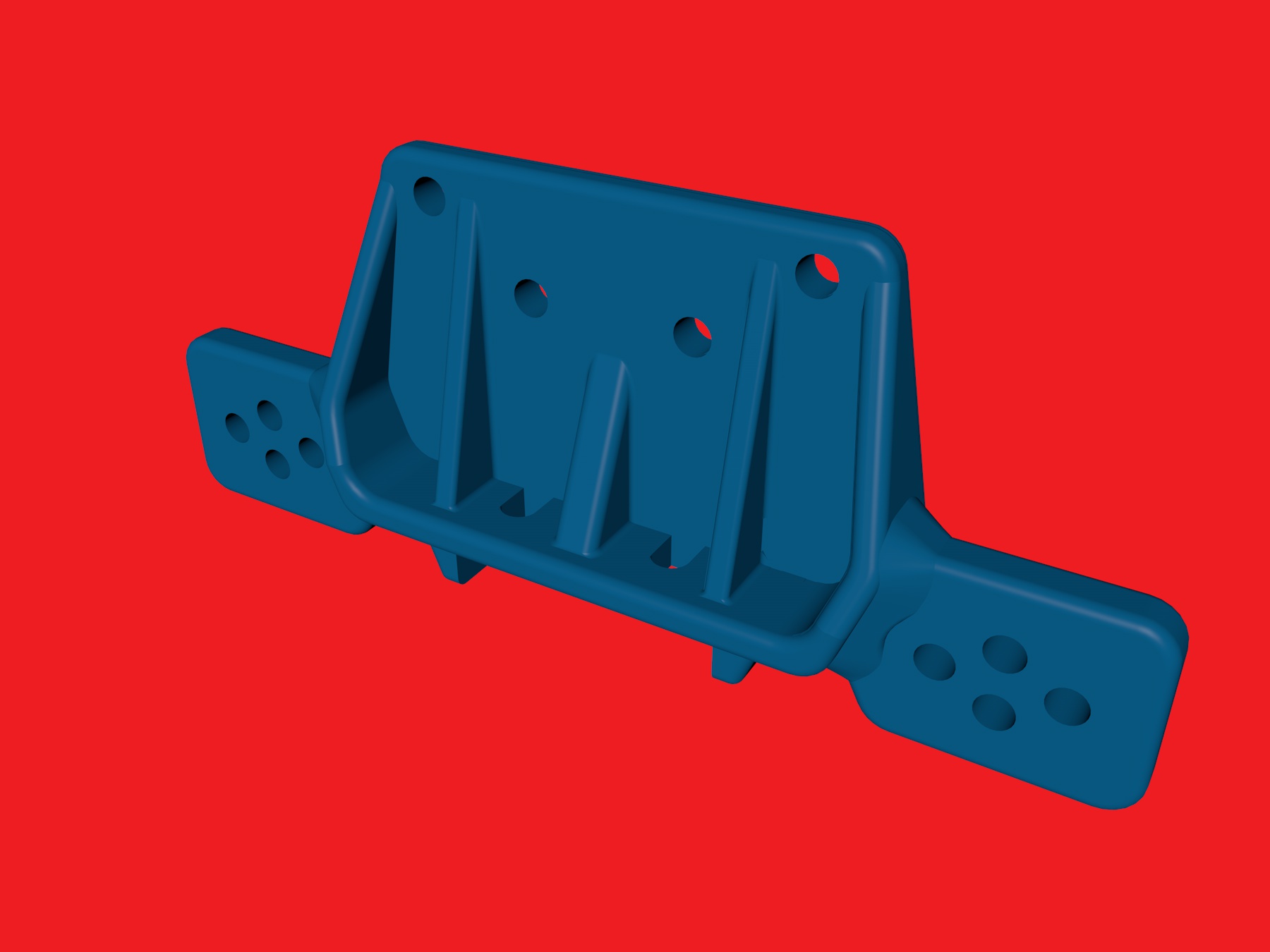

Since 3D printing reached a certain level it made totaly sense to draw parts in 3D engineering software, modify and reinforce neuralgic points.

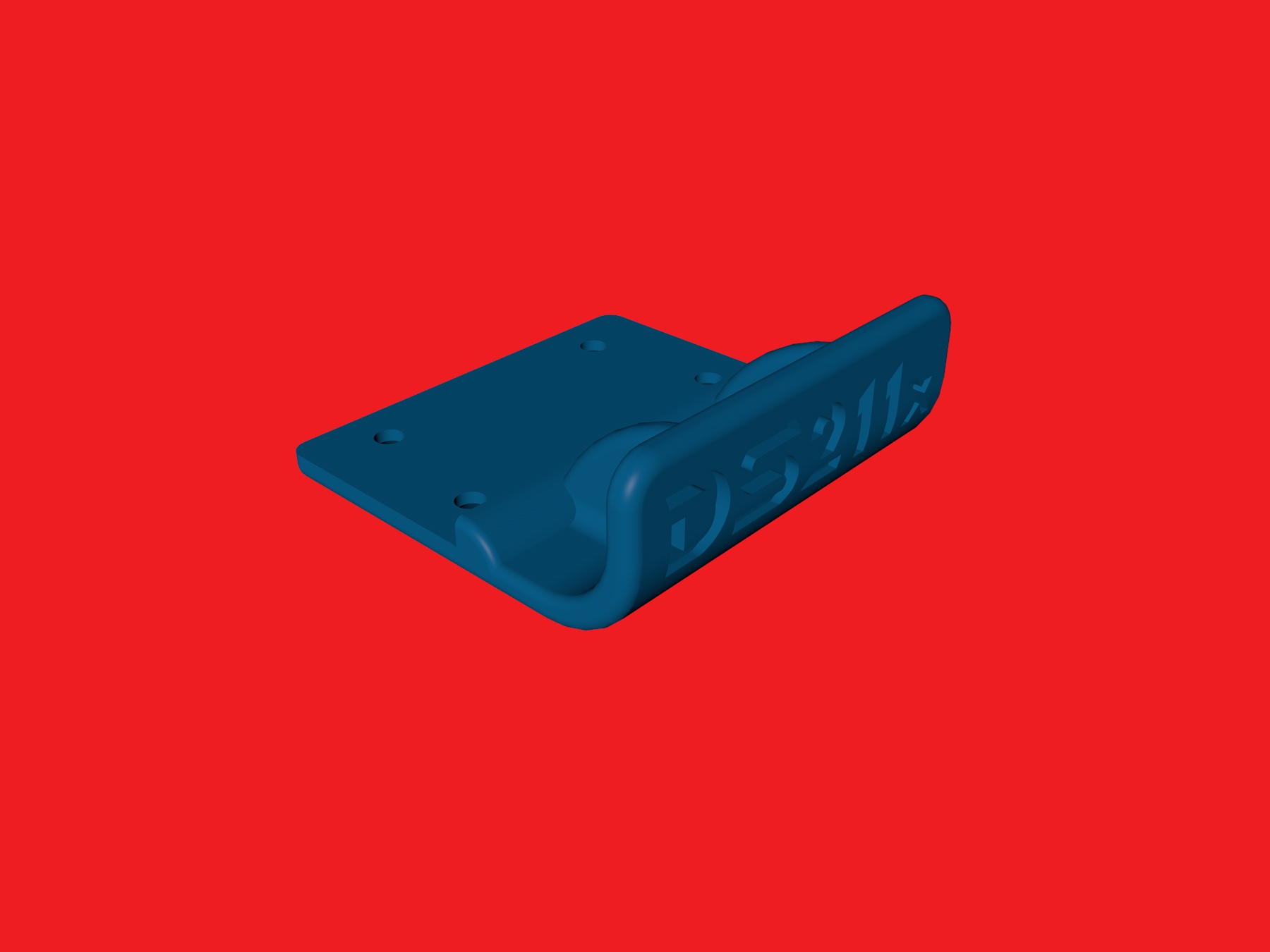

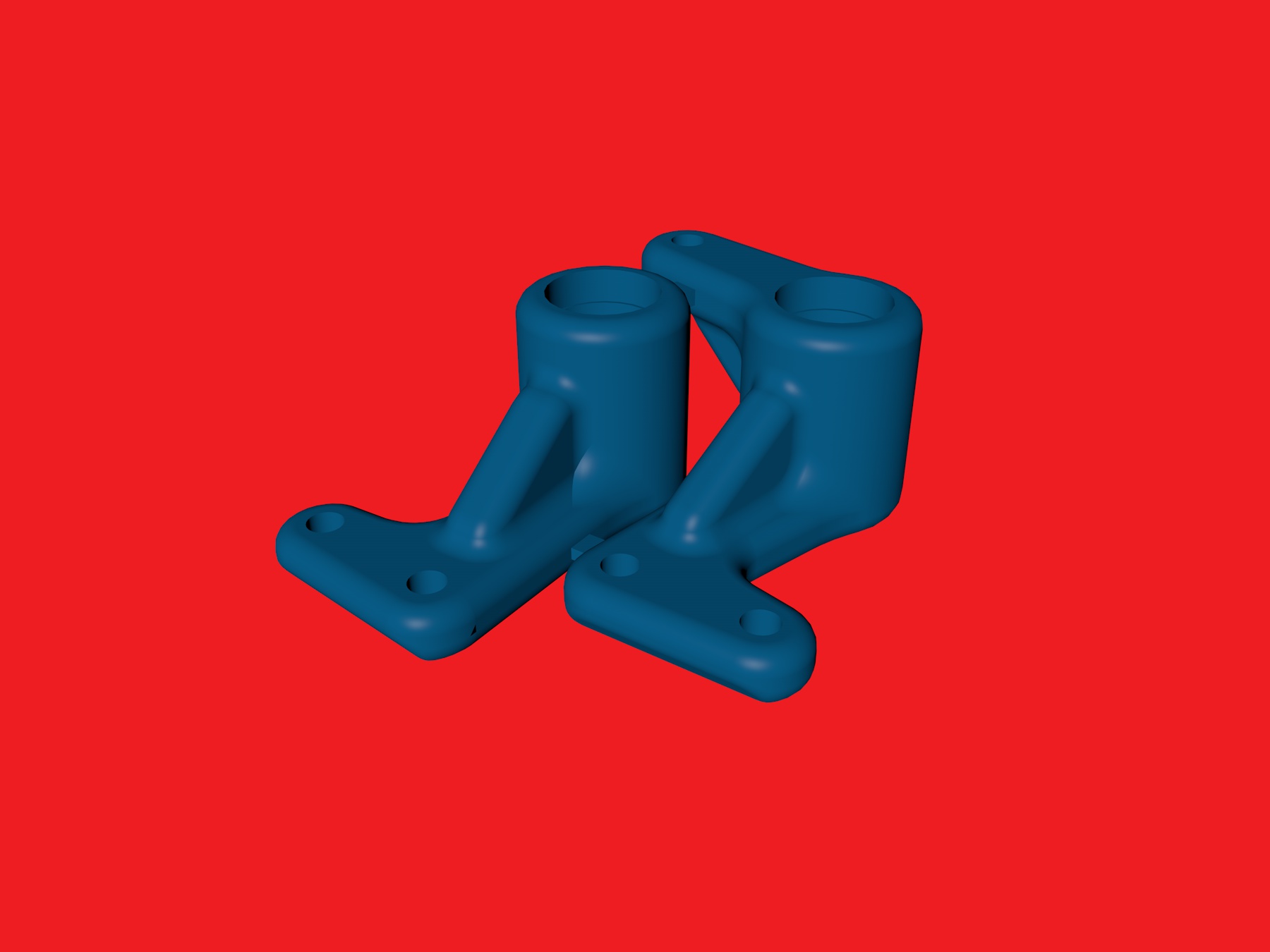

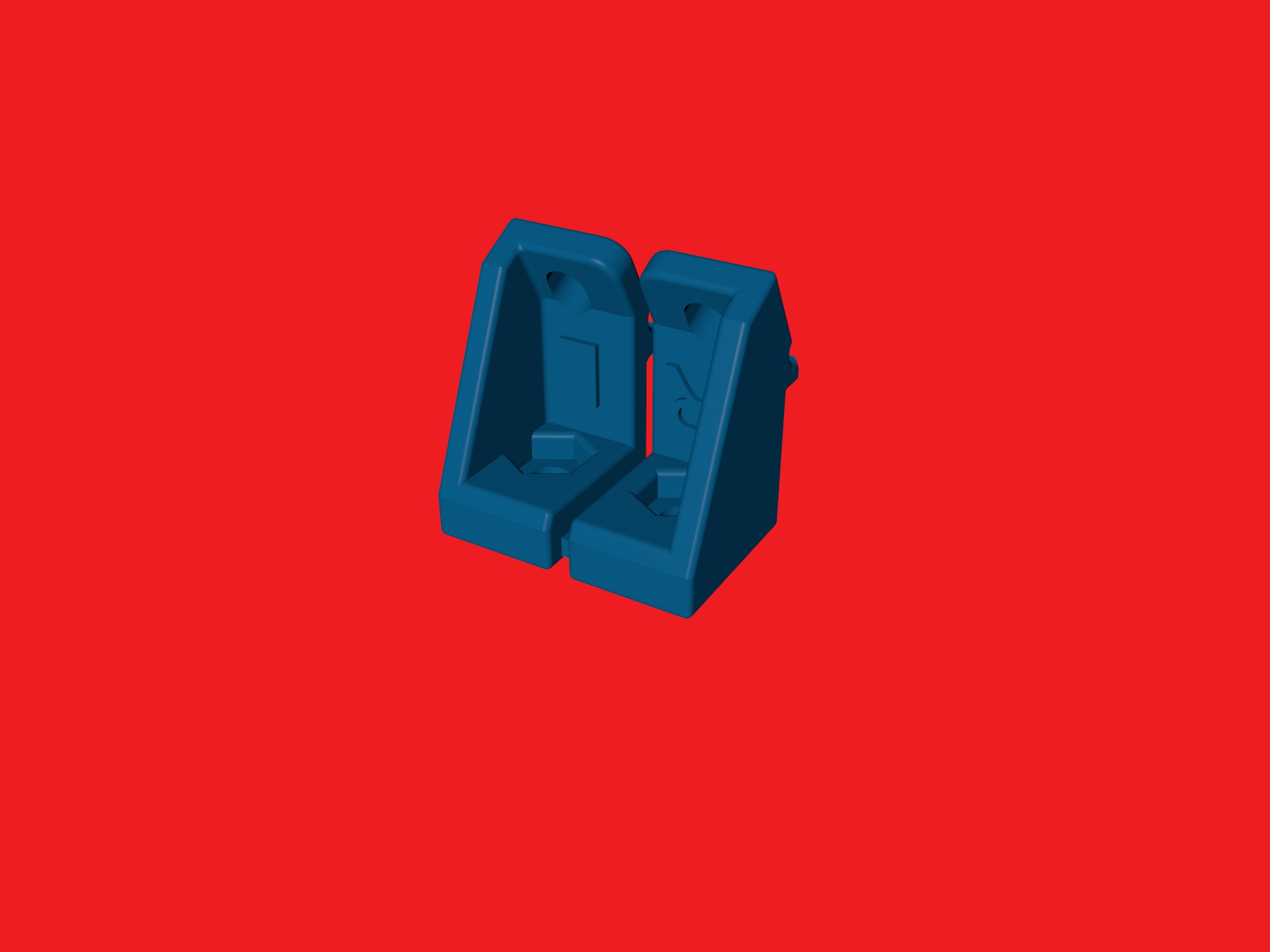

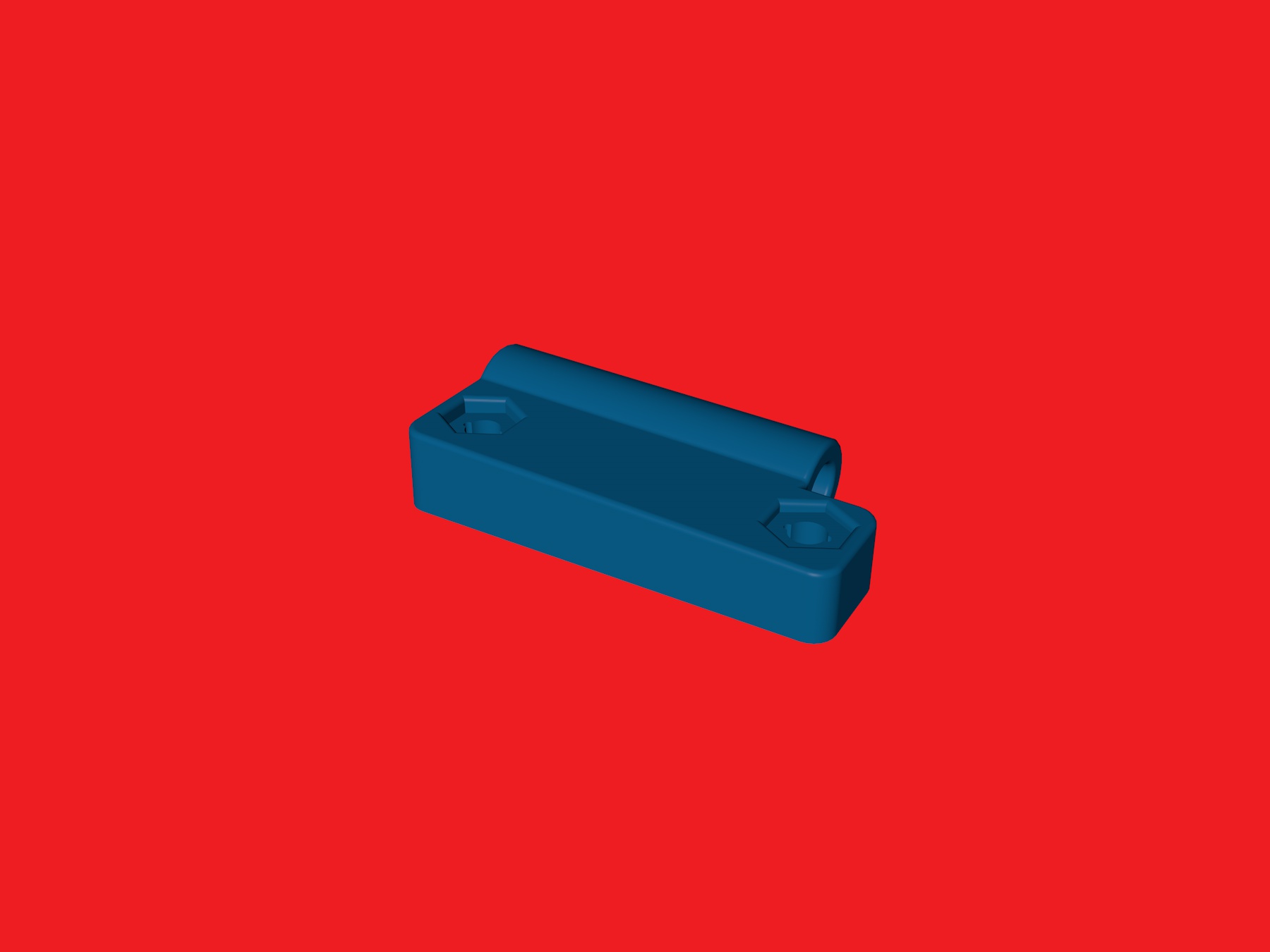

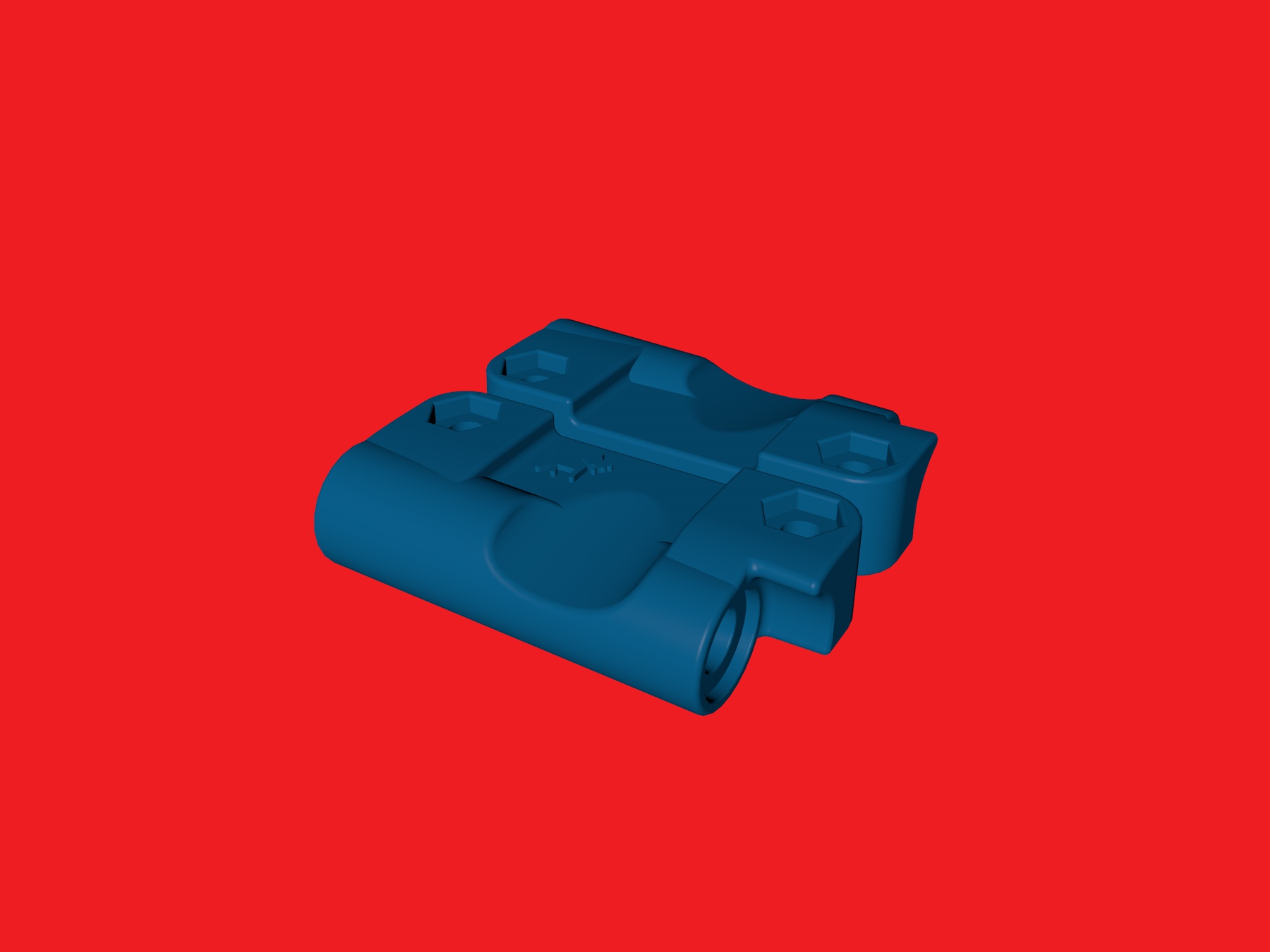

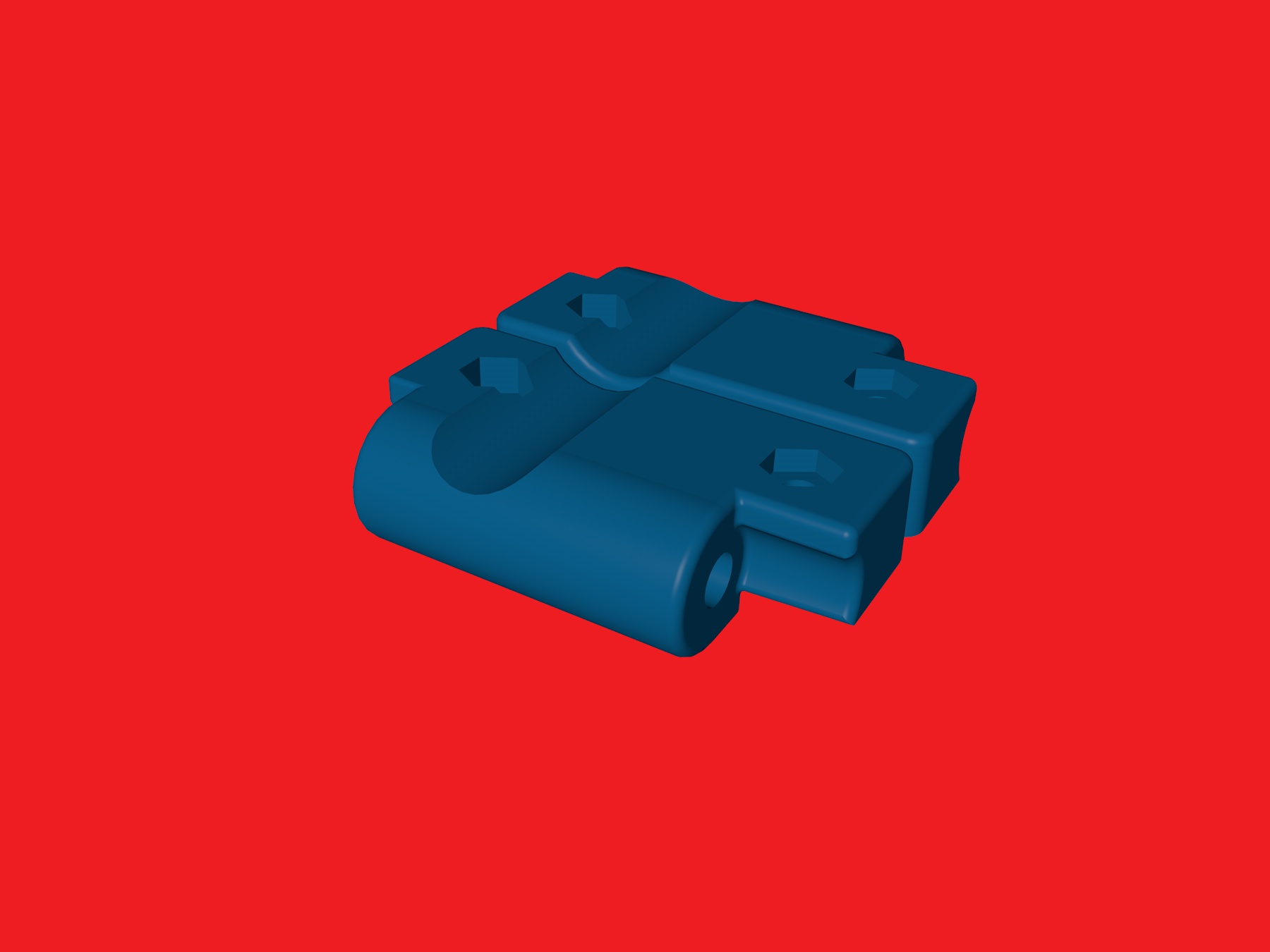

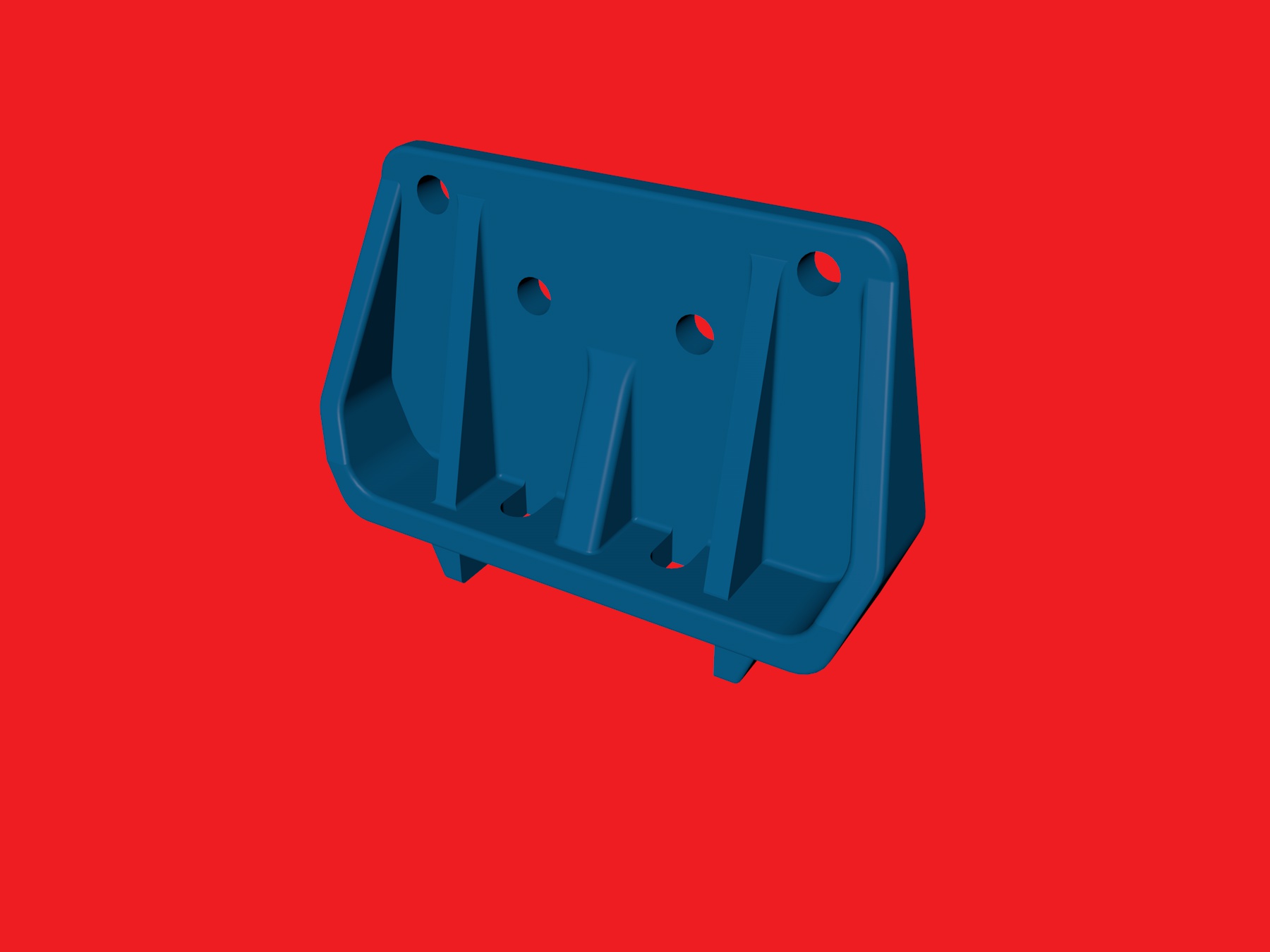

Usually I do FDM prints on my PRUSA MK3S for prototyping but some materials like carbon fiber reinforced filament or even PETG are strong enough to replace parts to keep the Dyna running. FDM printer extrude melted filament and it sticks together path by path. Bottom surfaces does not have the perfect look inherent this additive technique.

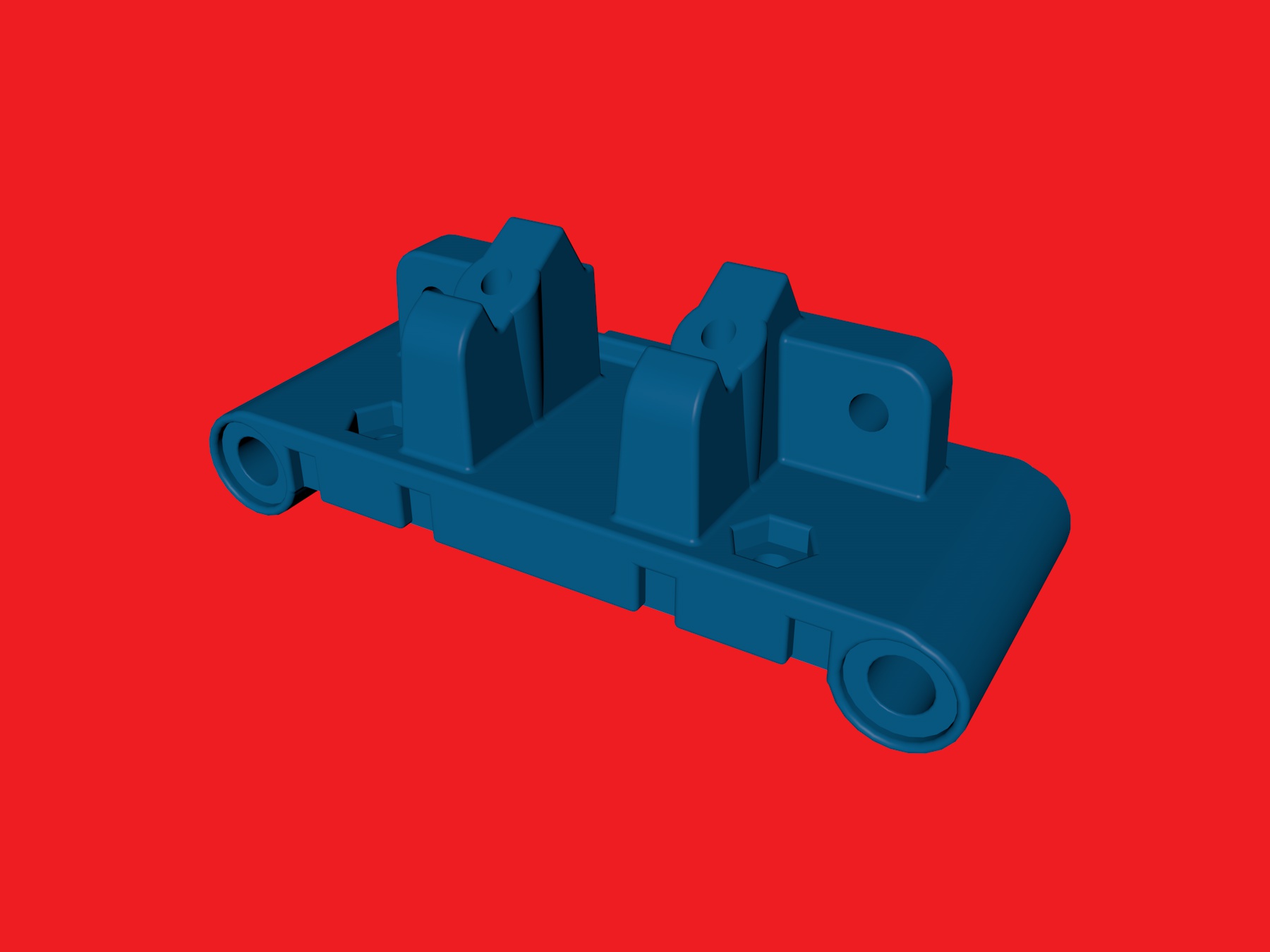

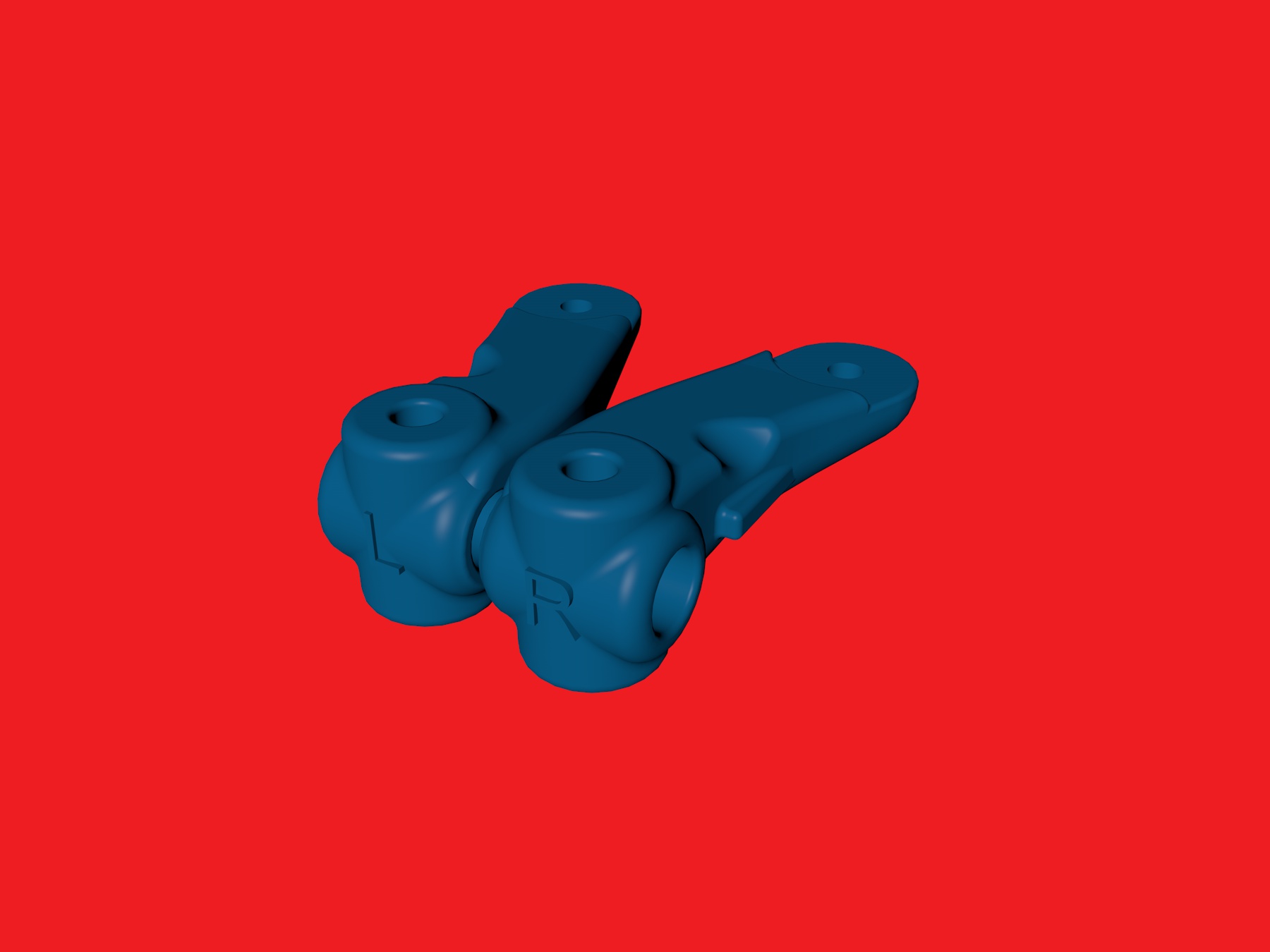

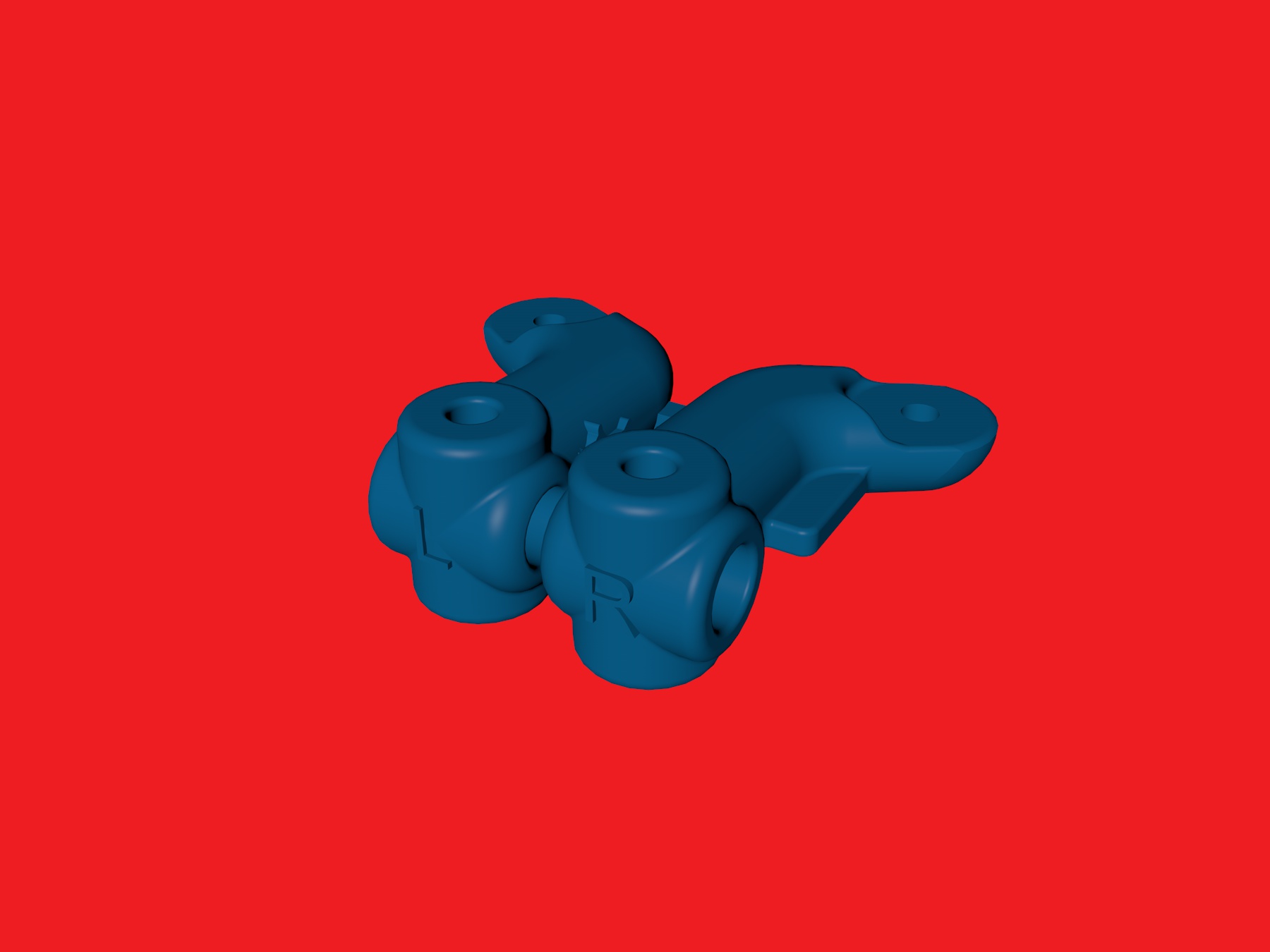

SLS or MJF prints are more advanced industrial quality with optimal surface finishing. Layer by layer they melt nylon PA12 powder together and create a solid object. Usually it is this kind of prints you know from Shapeways.

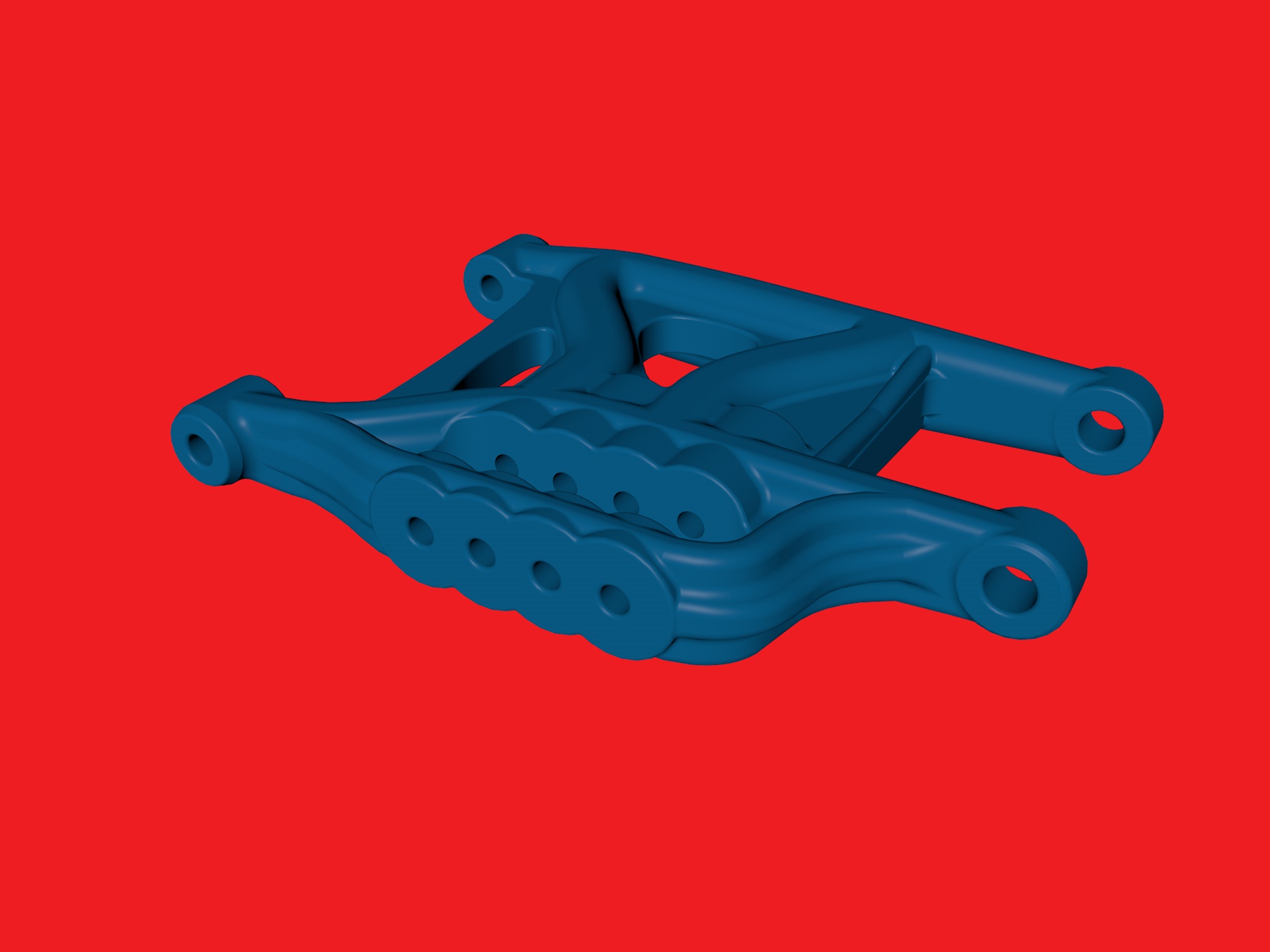

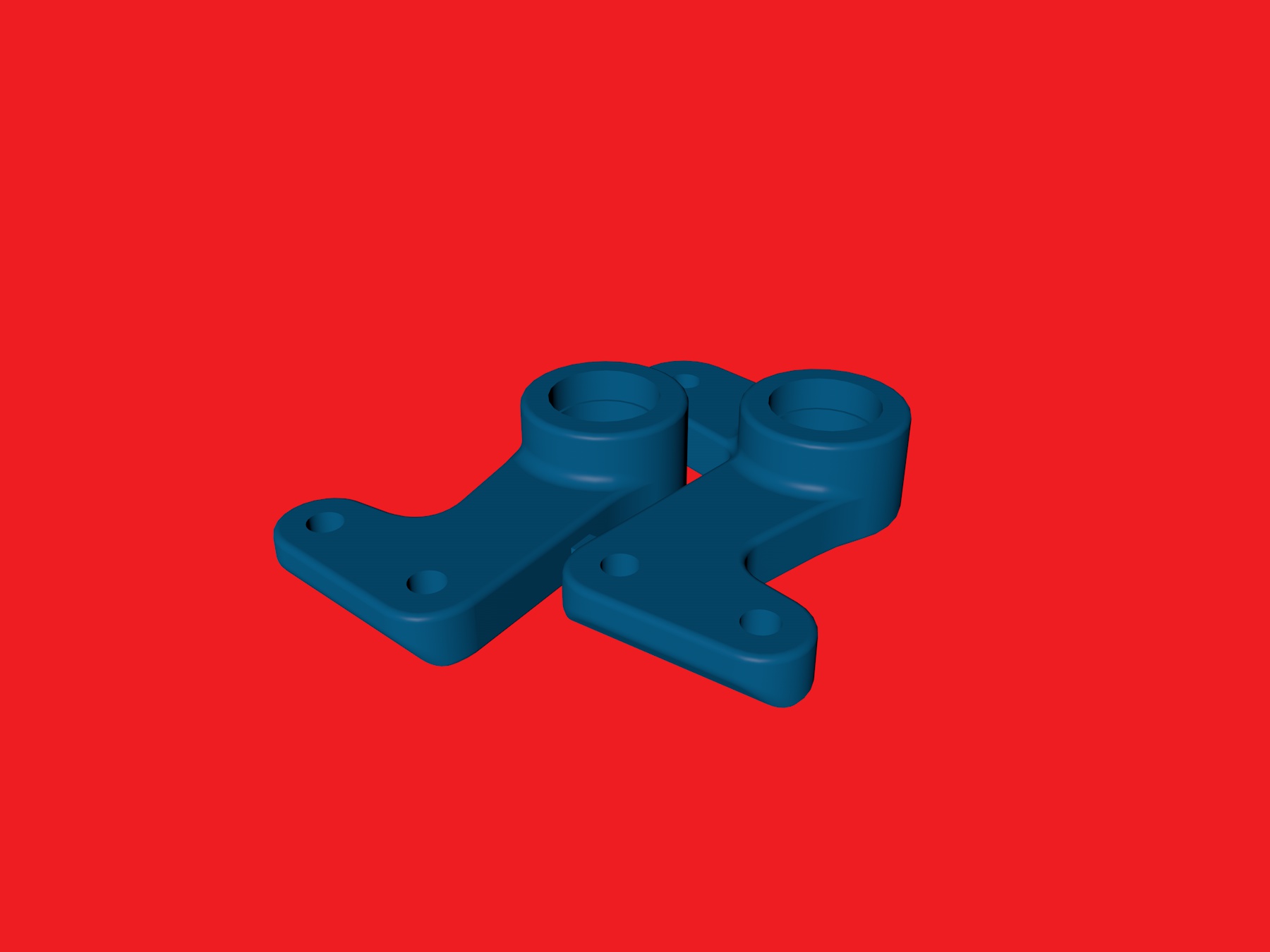

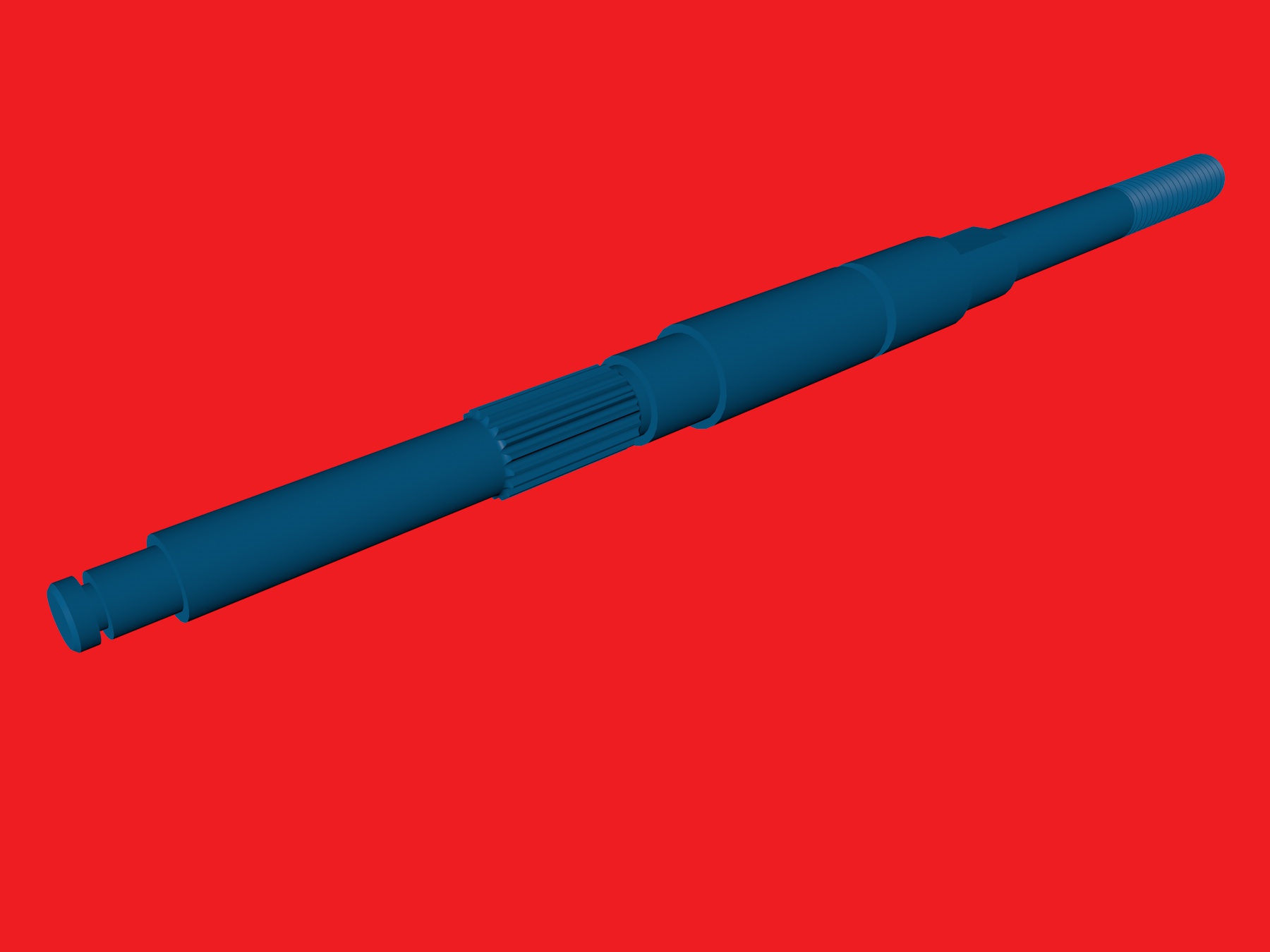

In some certain cases there is the need for high strength aluminum parts. Therefore CNC machining is the way. It is pure luxury, expensive but the result is stunning.