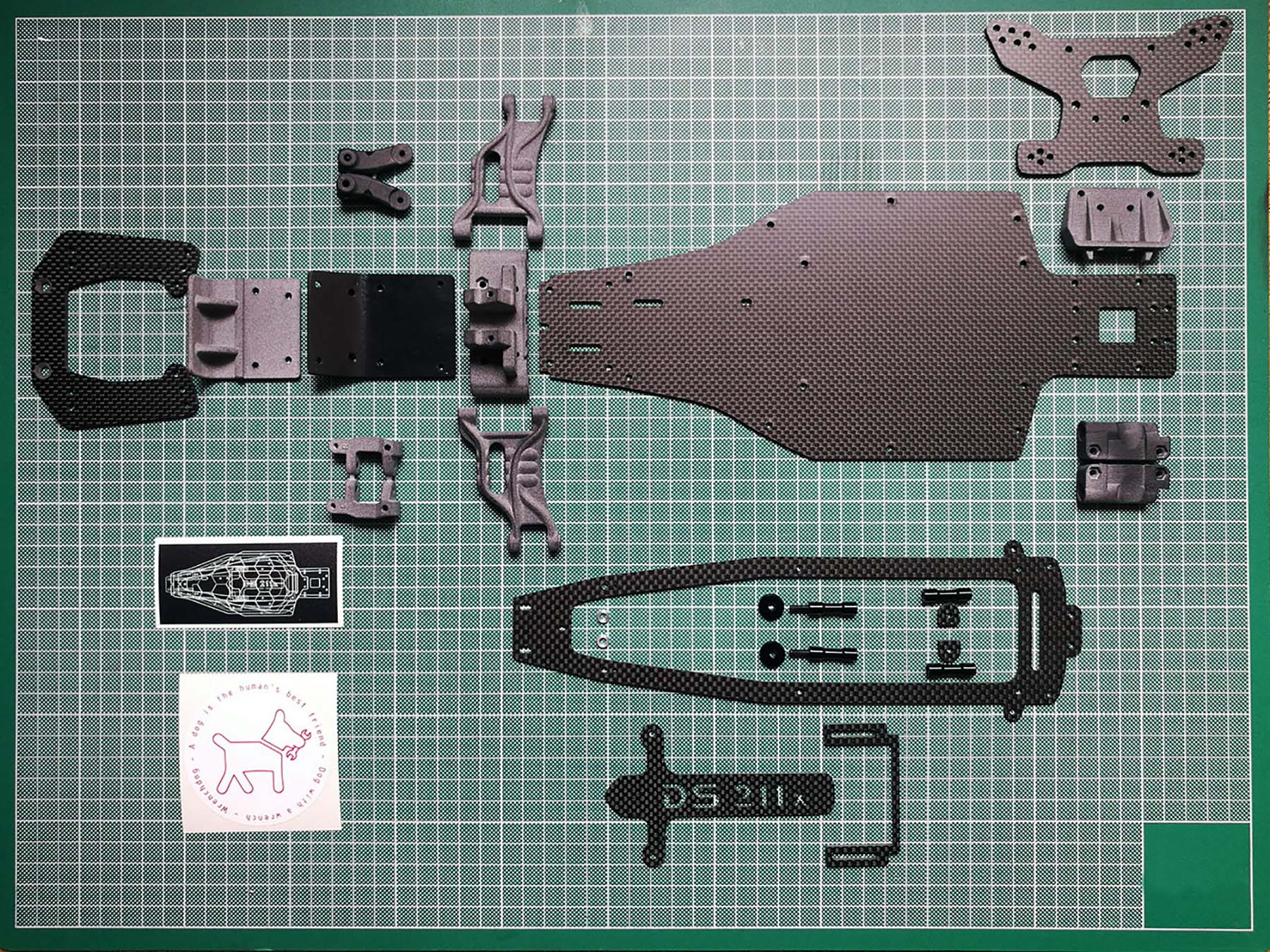

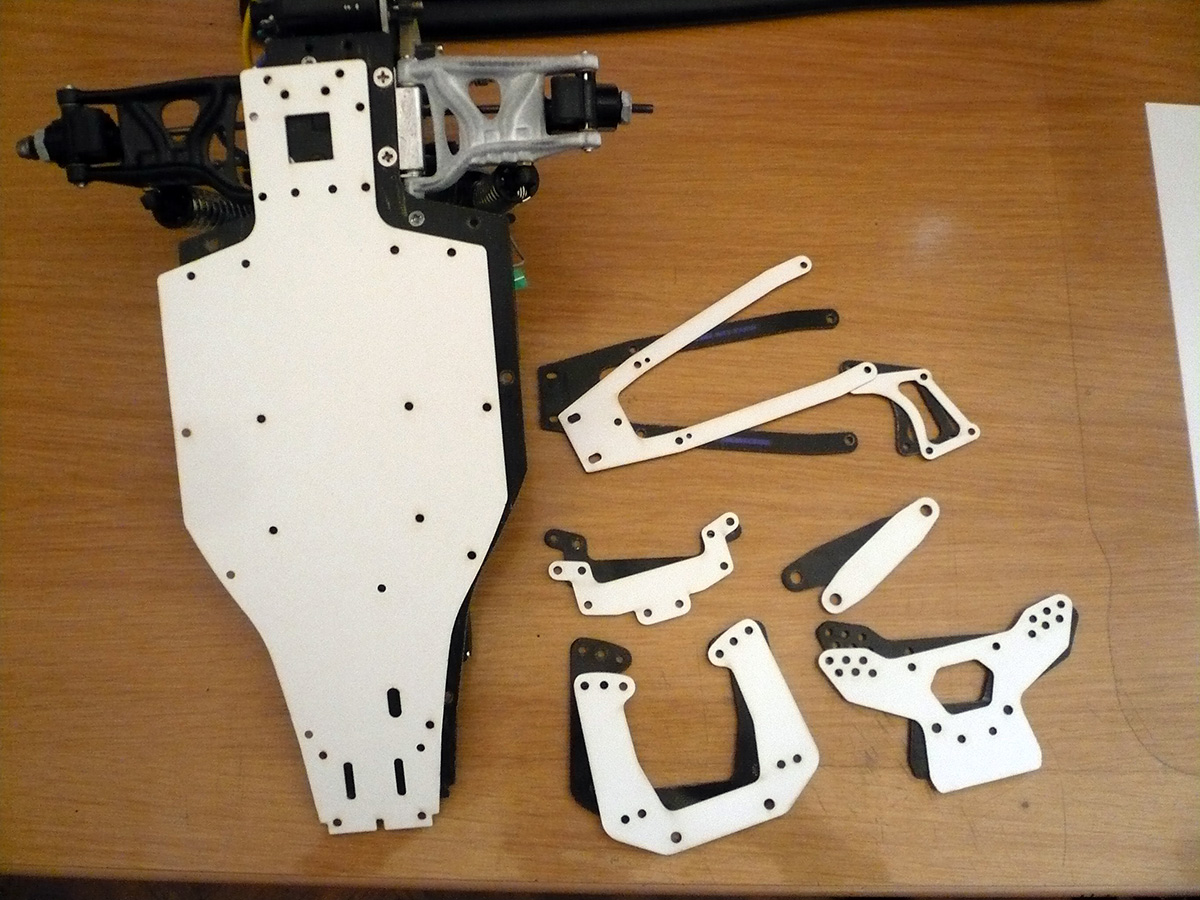

The Dynas are pretty special for me because of the combined use of some very interesting materials such as Fiber-reinforced composite. This gave them a more exquisite look and a different position in compare with other “full plastic” models.

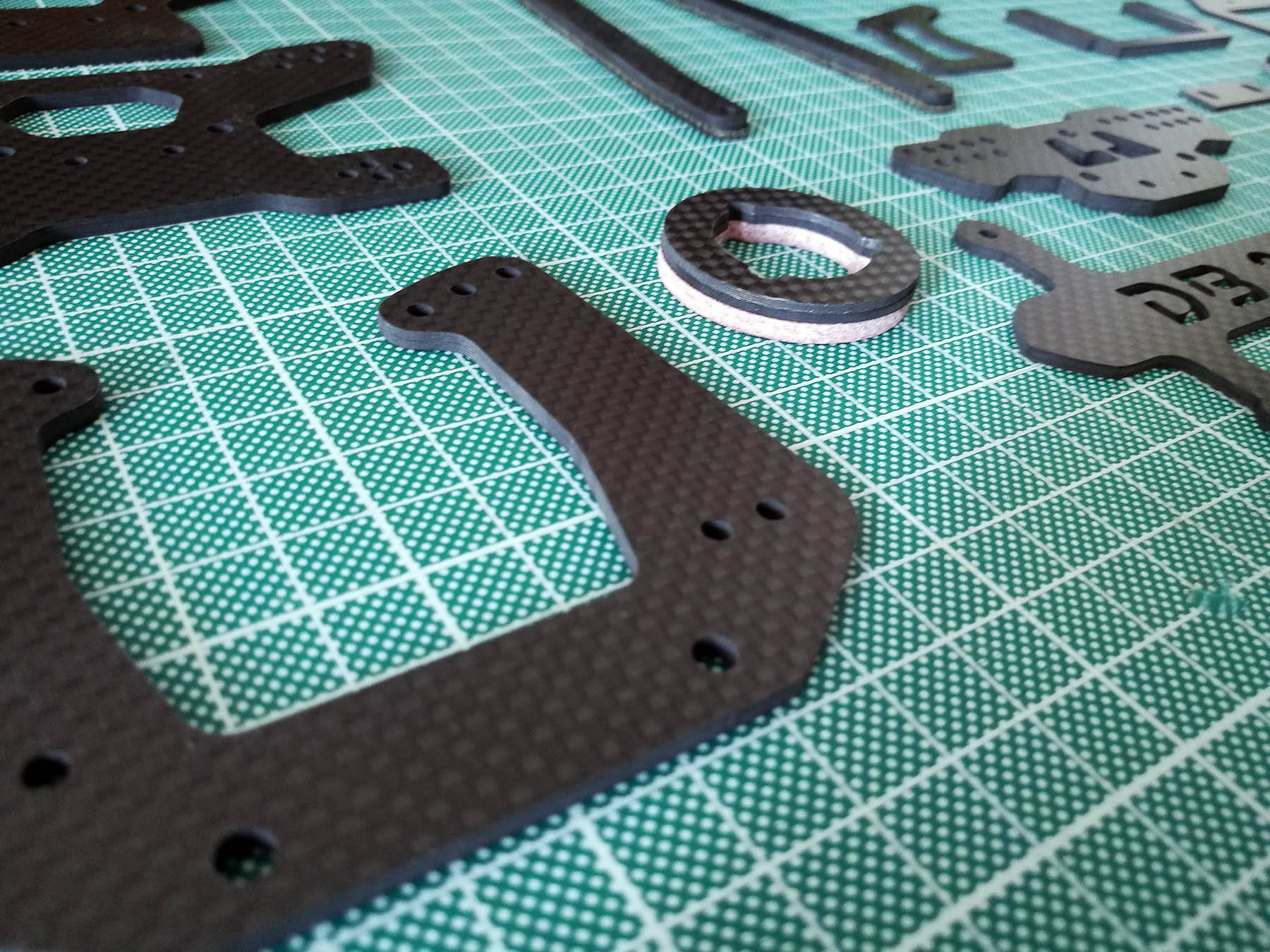

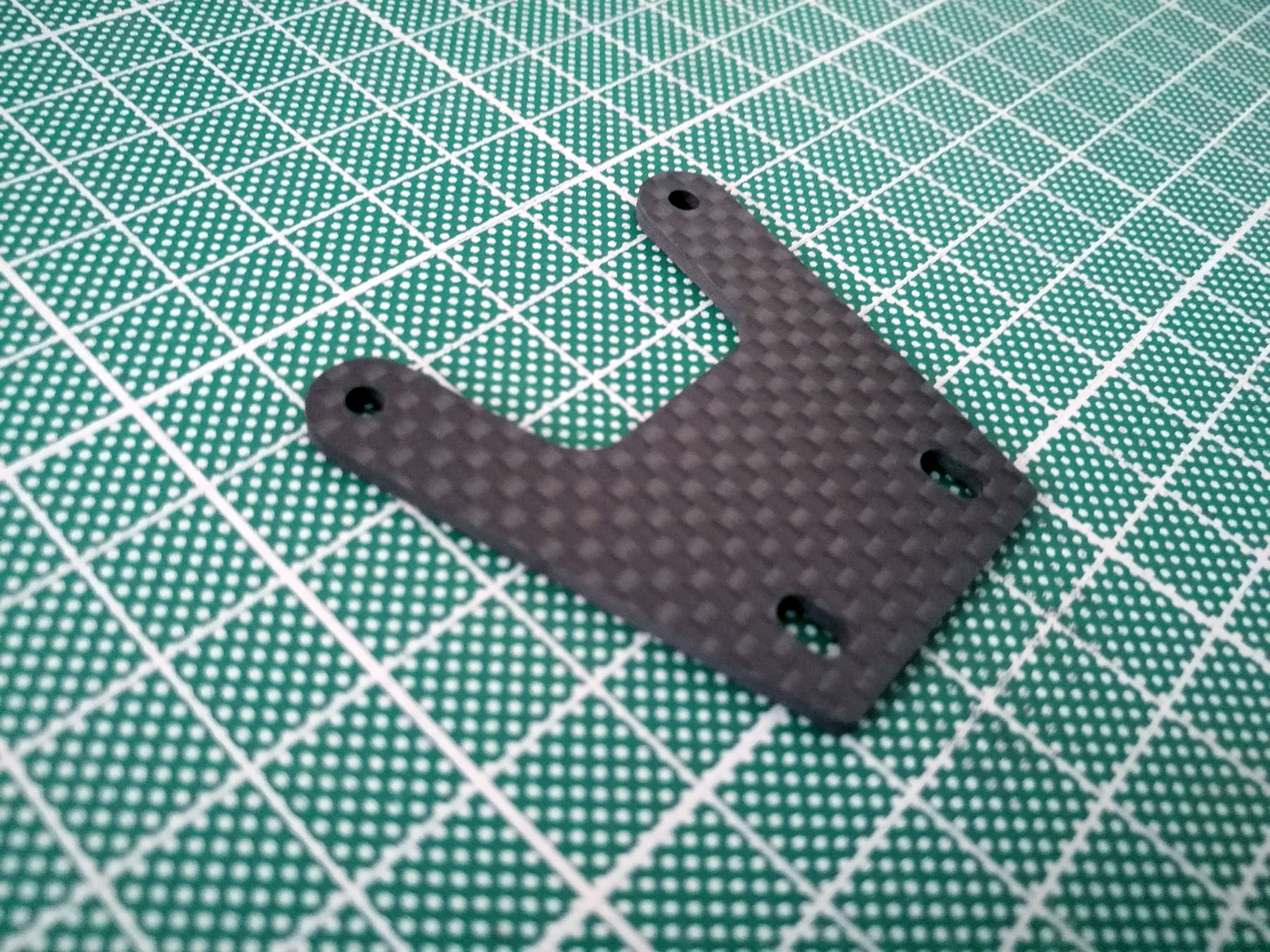

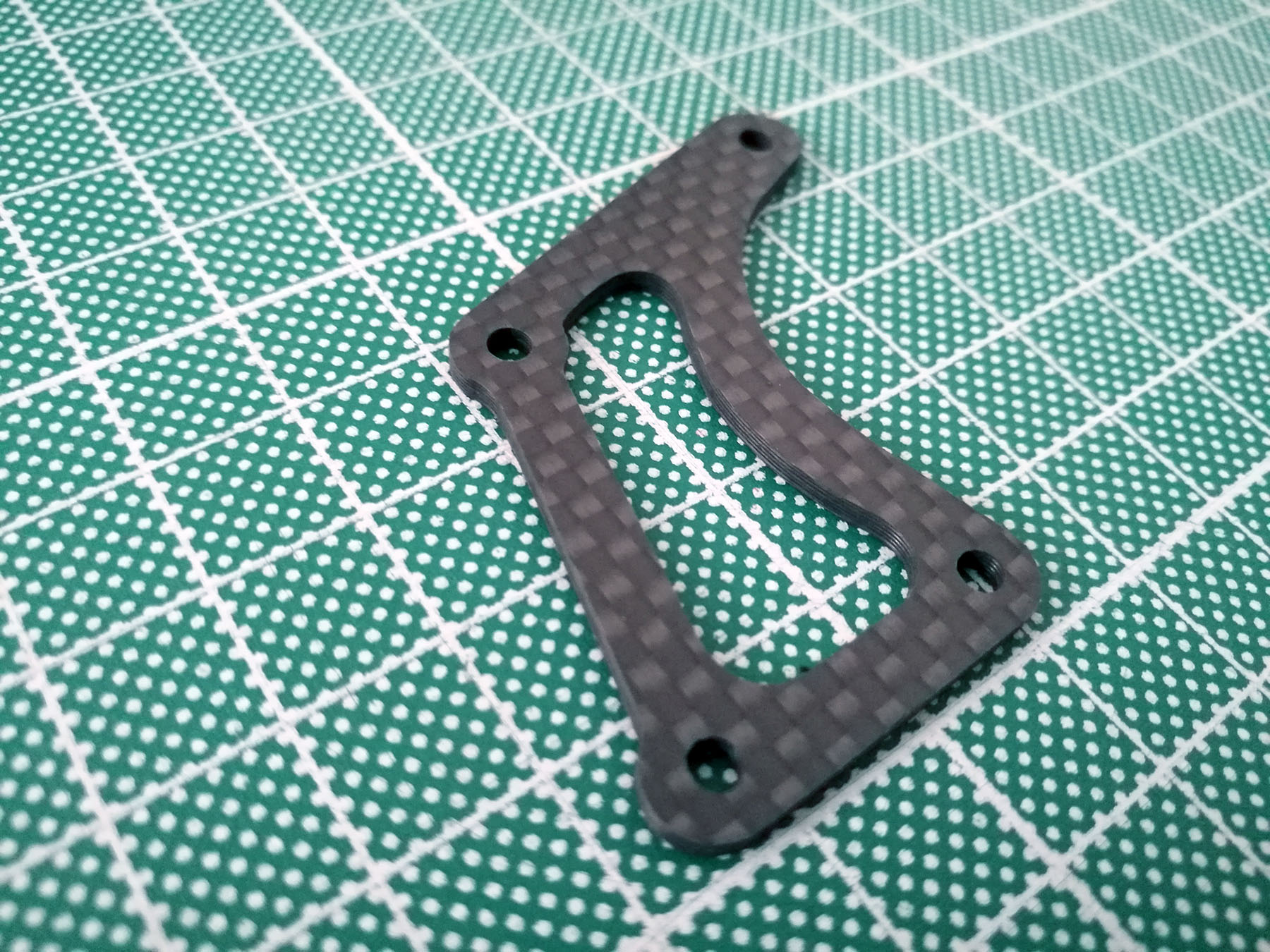

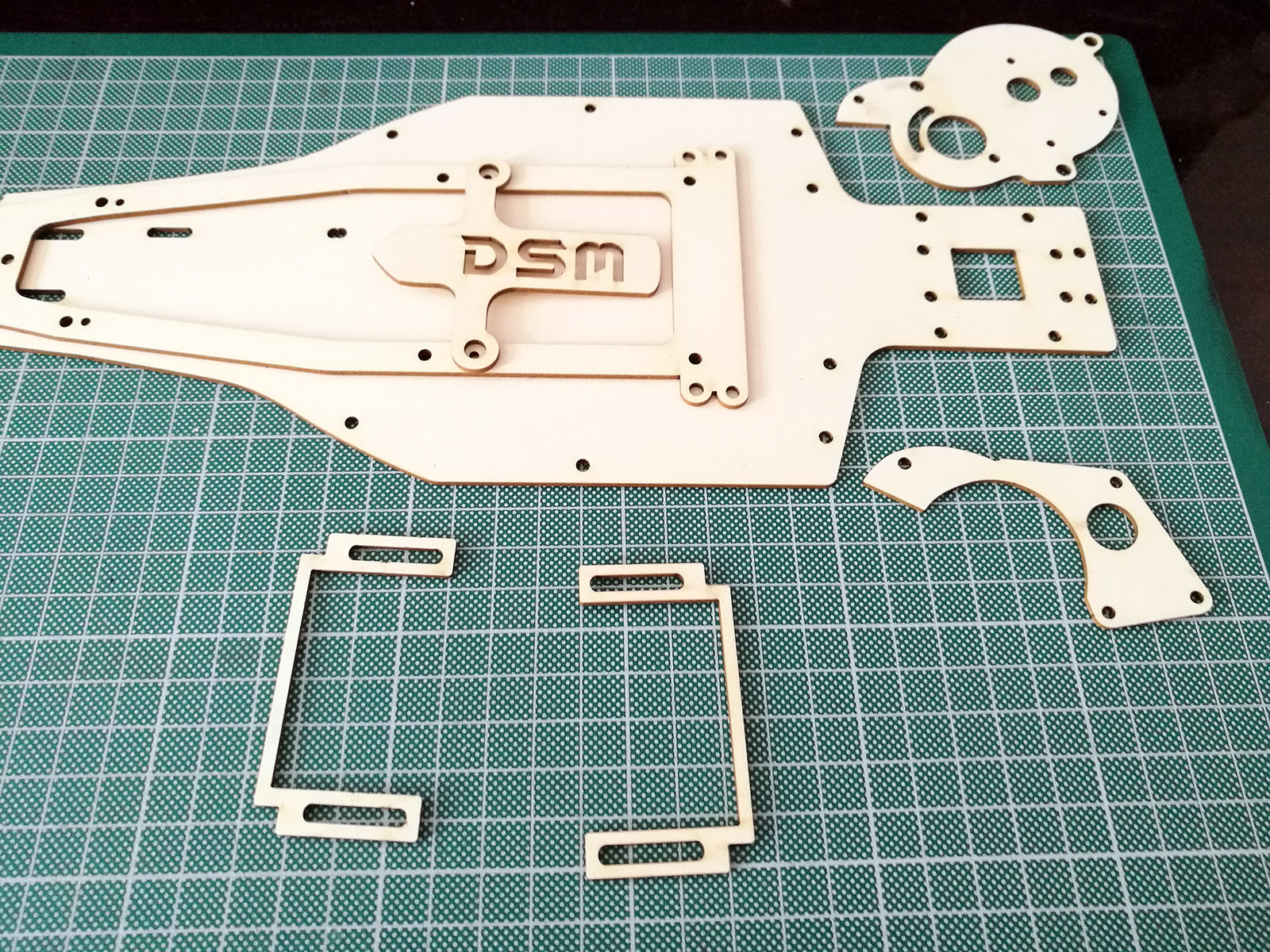

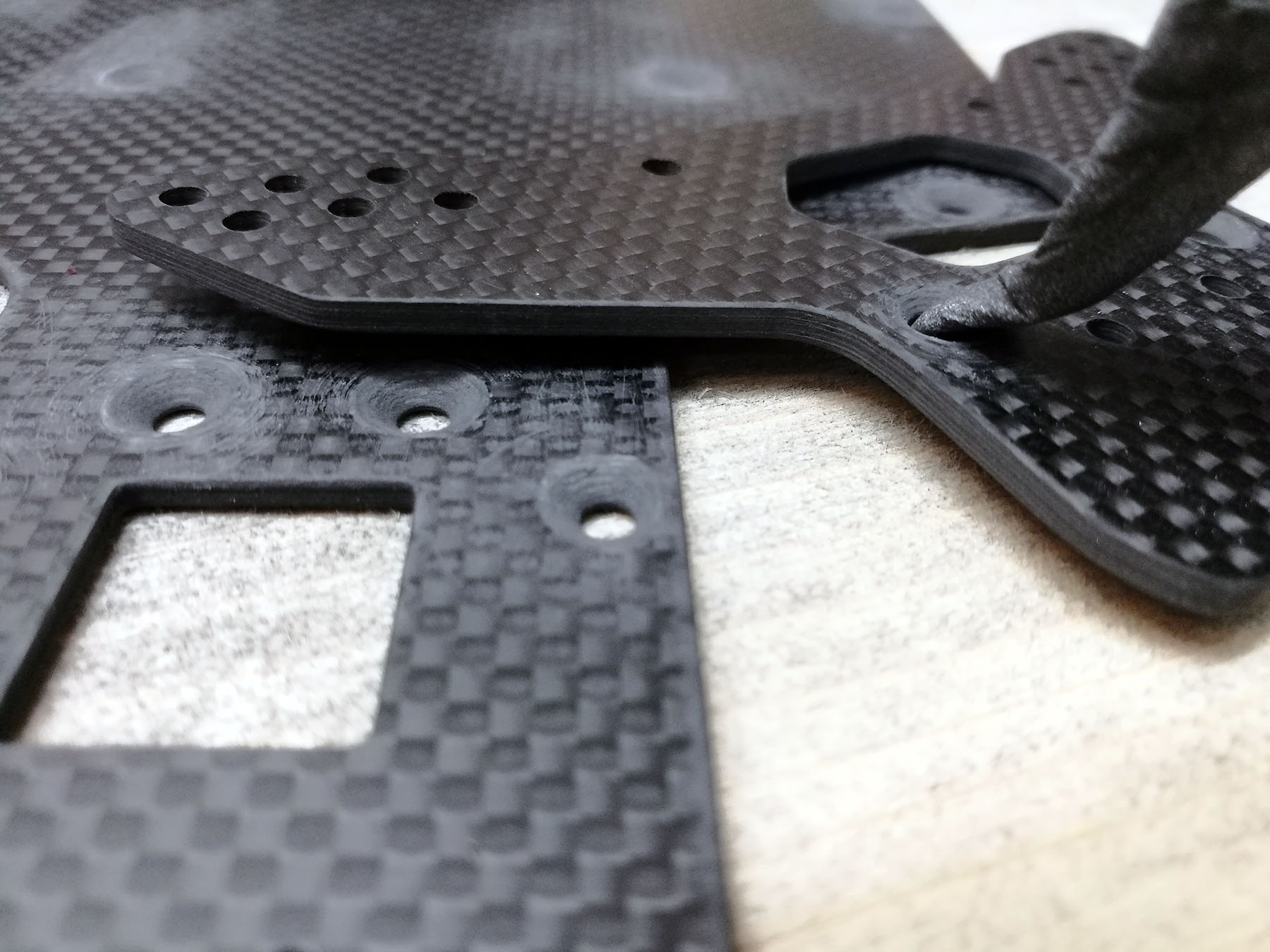

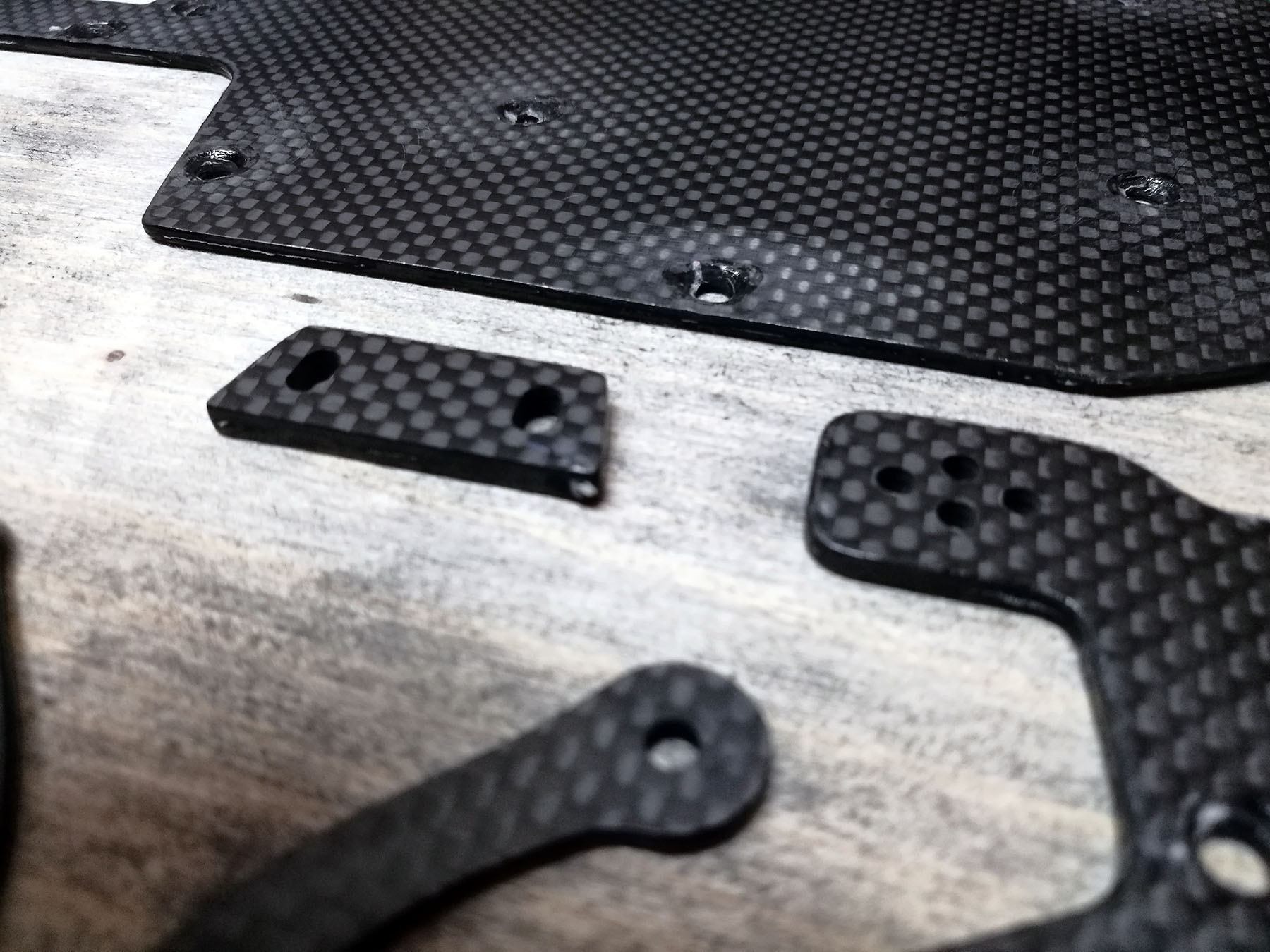

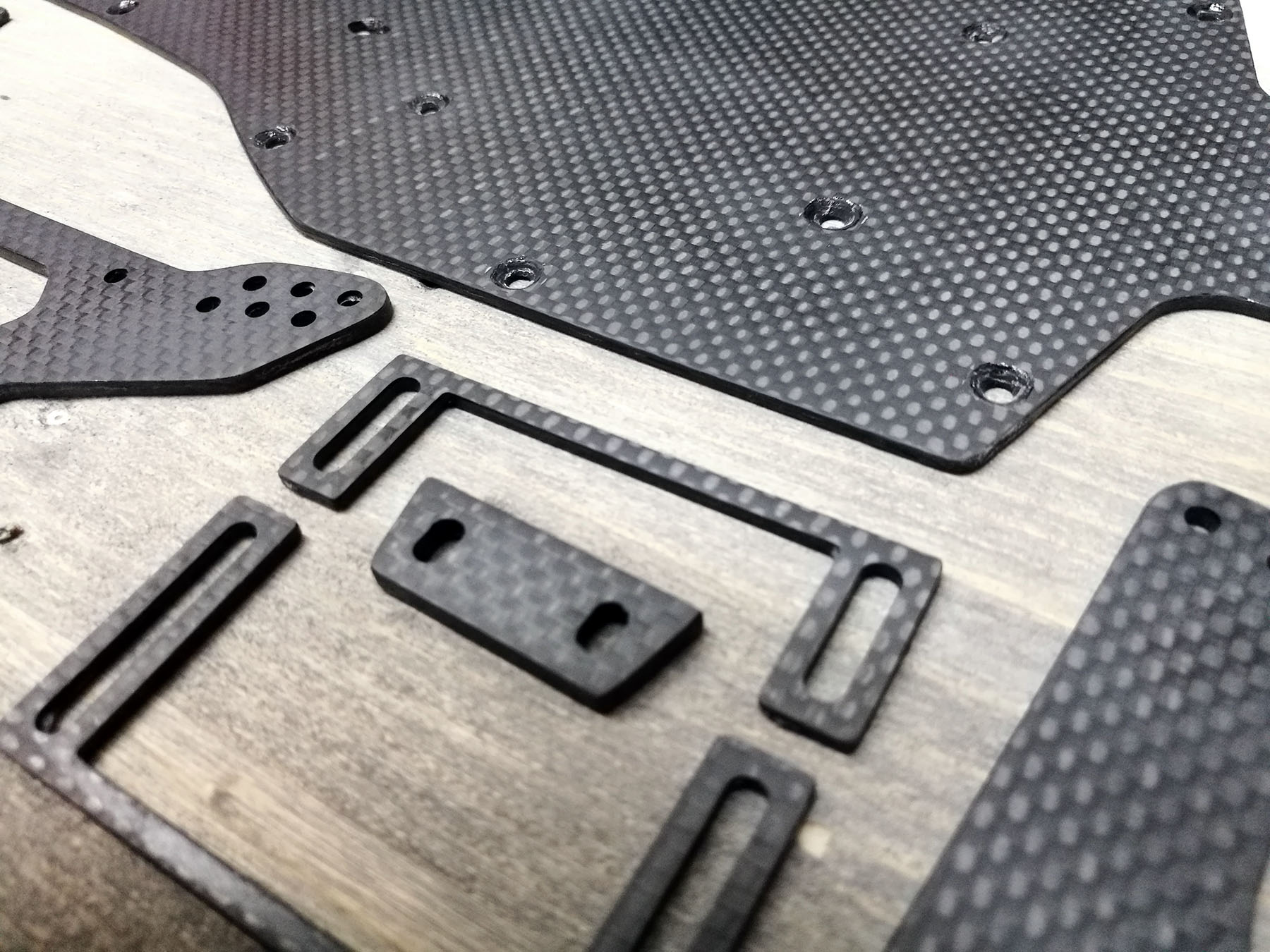

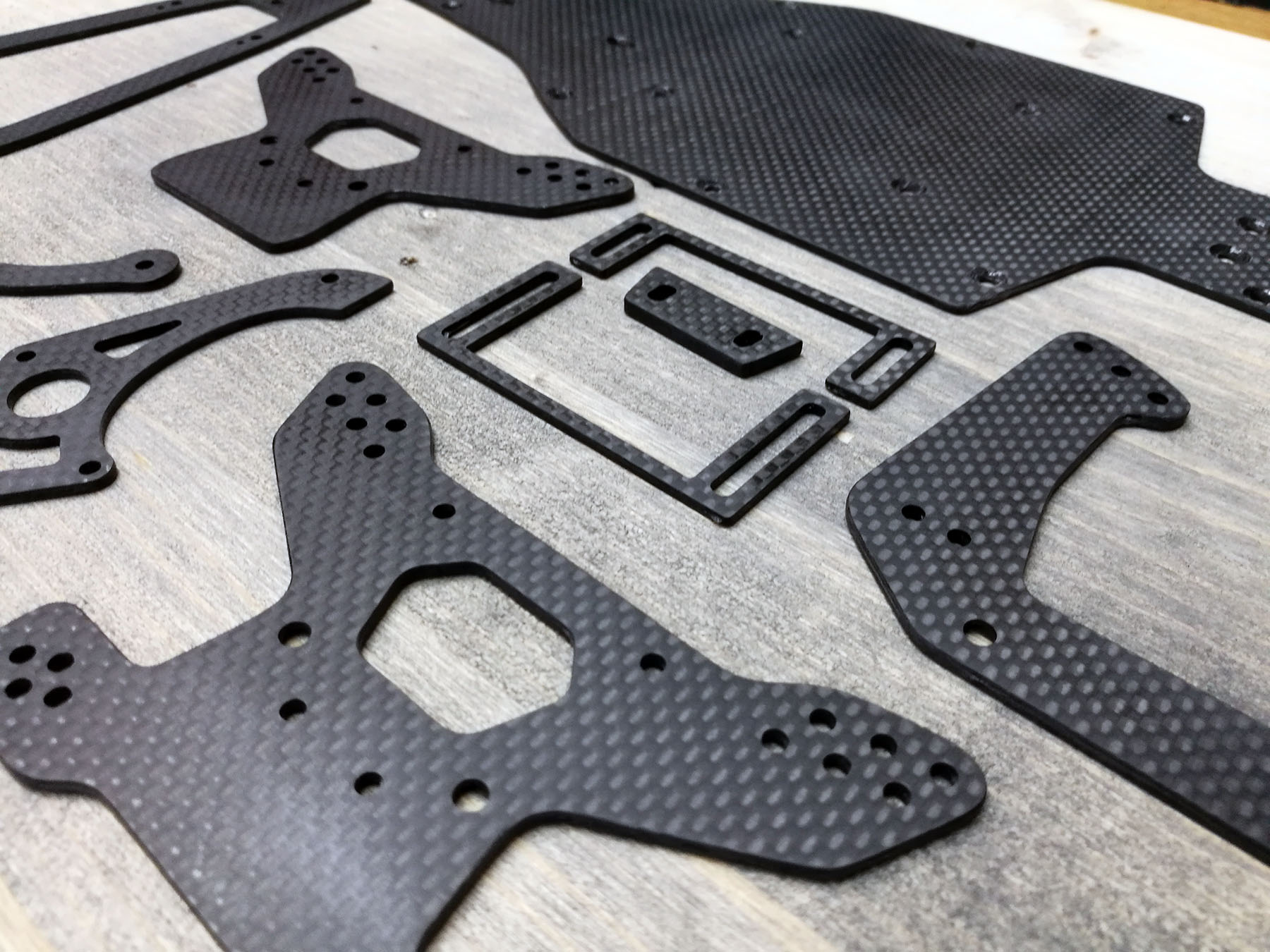

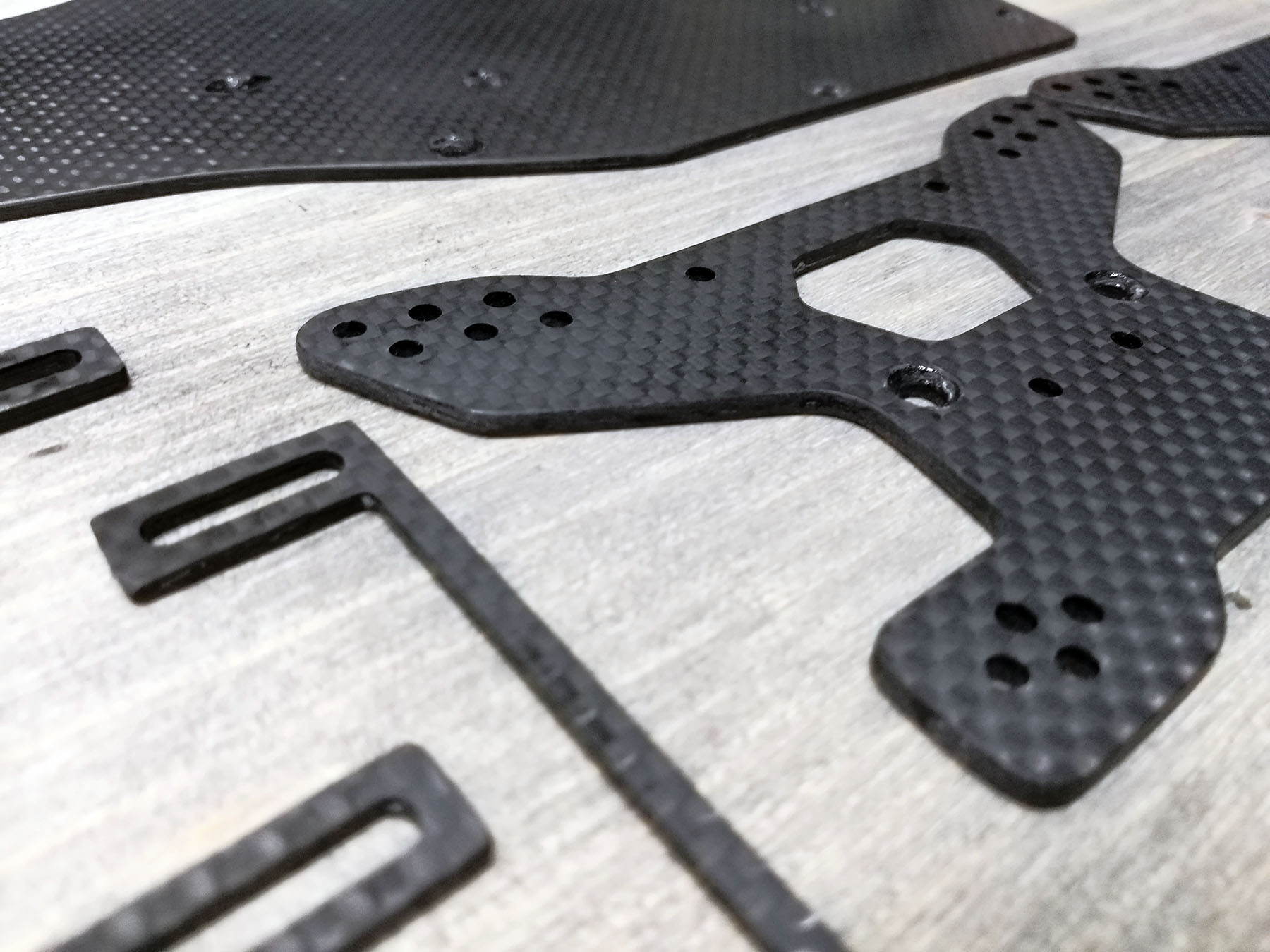

Nowadays there are much better carbon fiber plates available then back in the 90s. Usually I use single twill fabric in matt, they do their job pretty well. Some parts like TR-15T front damper stay are reinforced around the upper damper mounts or the upper deck can be made for use of a large TGM/TNX nitro tank.

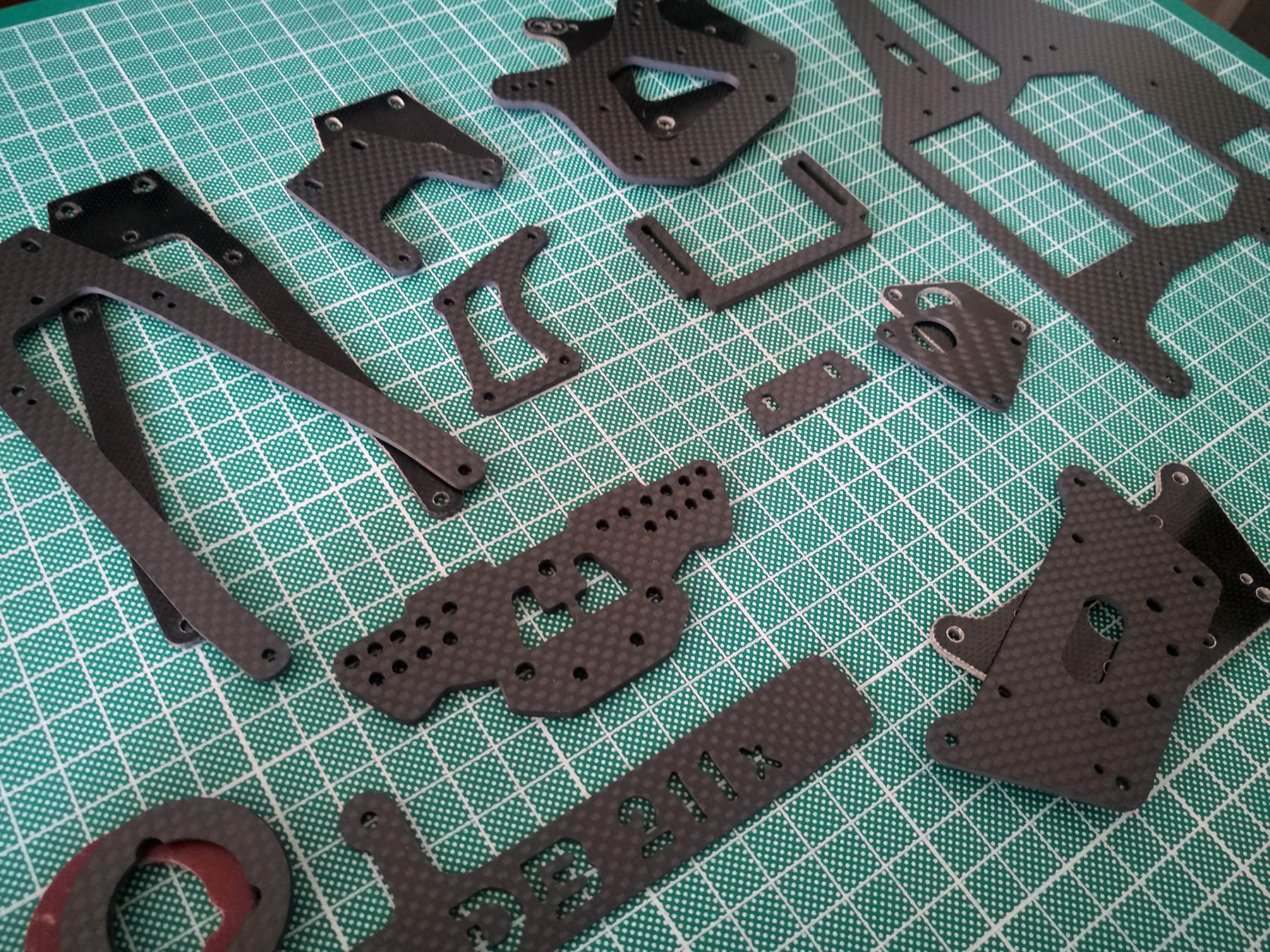

For my Dyna Blaster and Dyna Storm conversions I developed full carbon chassis and upper deck. Also the battery tray and braces are made of it. But also original replacement parts are made, such es full Dyns Storm set or TR-15T original upper deck and even break discs.

Choosing the right thickness for each part can make your Dyna from lightweight to nearly bulletproof heavy vehicle.

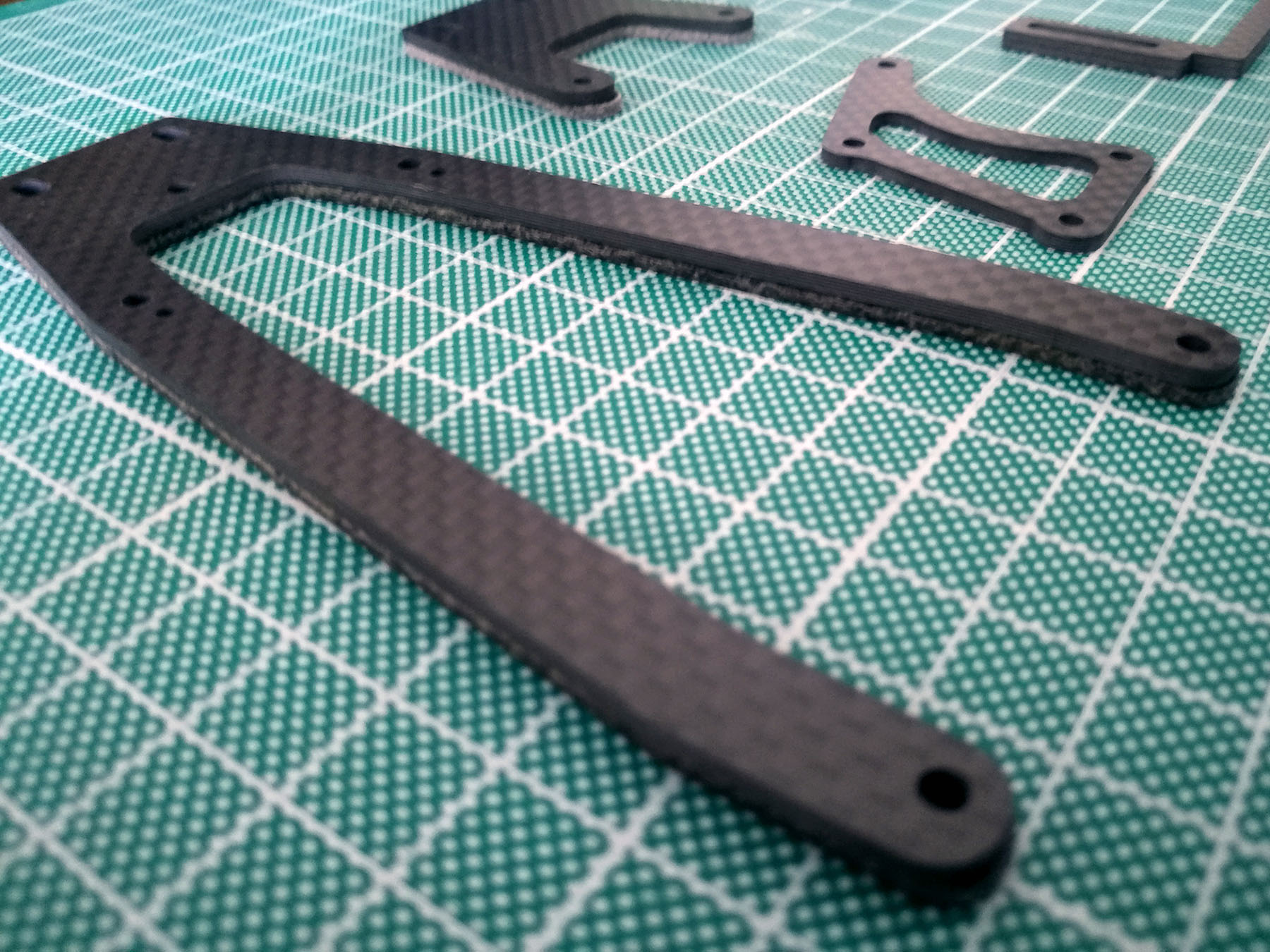

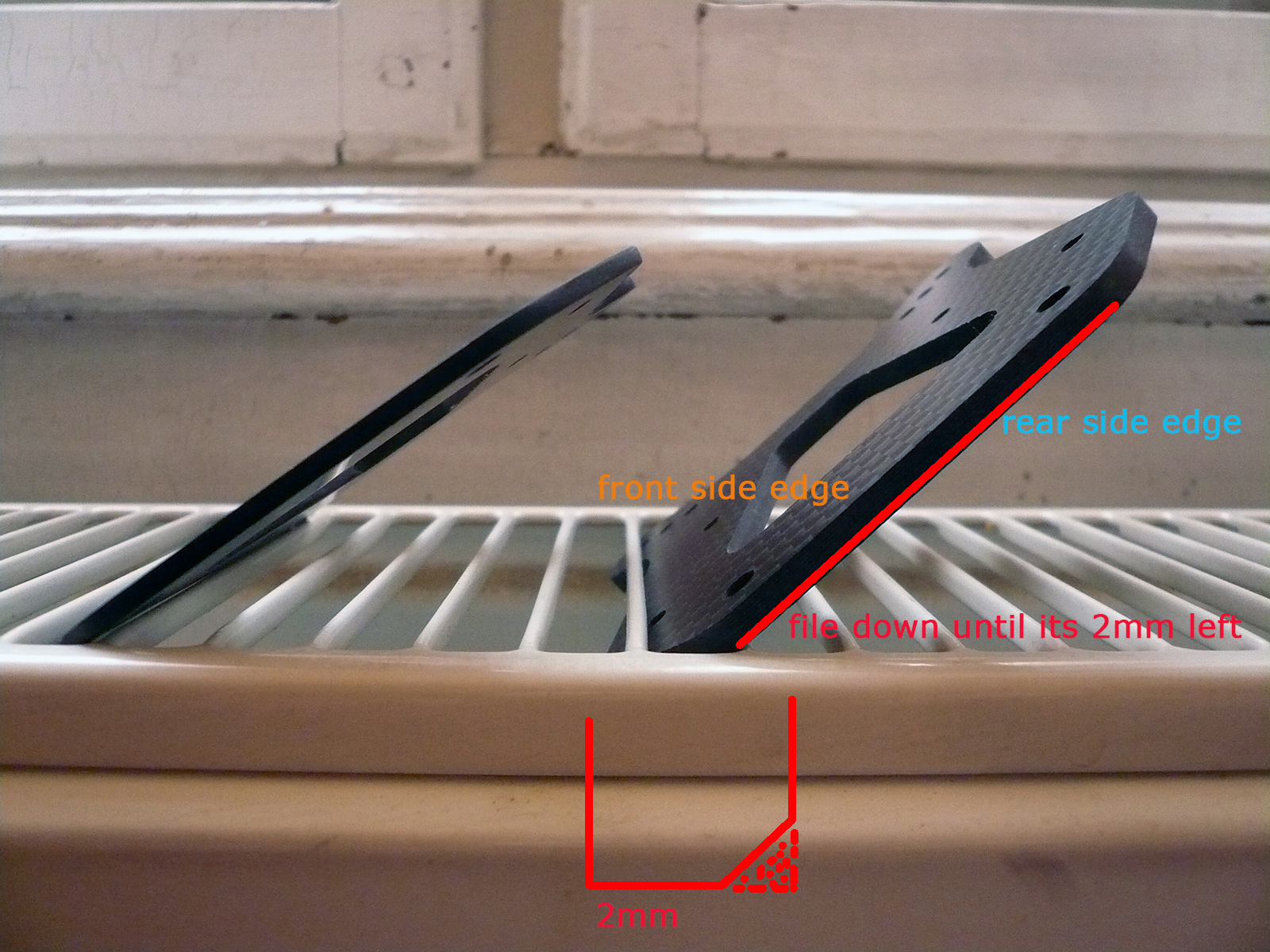

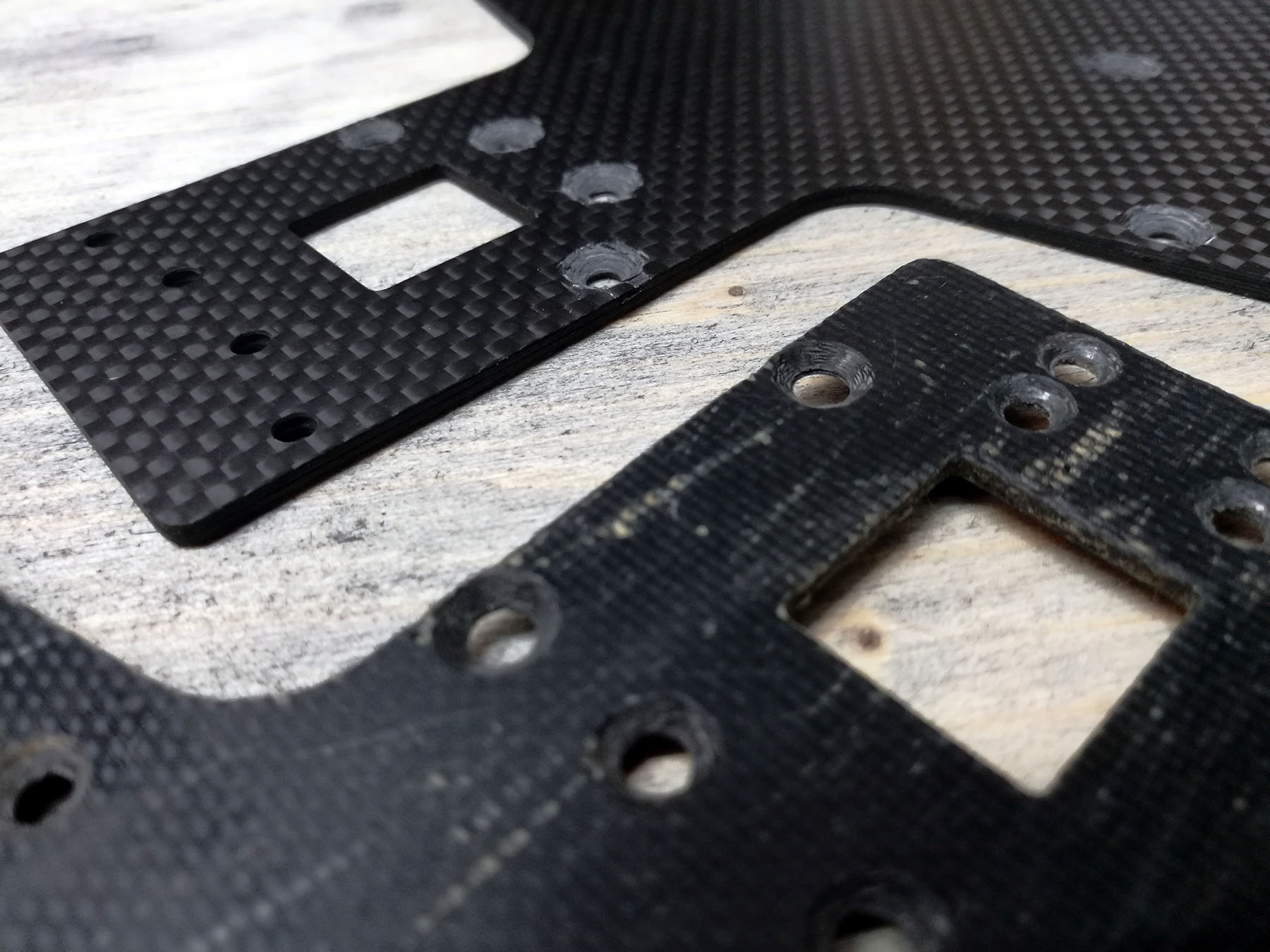

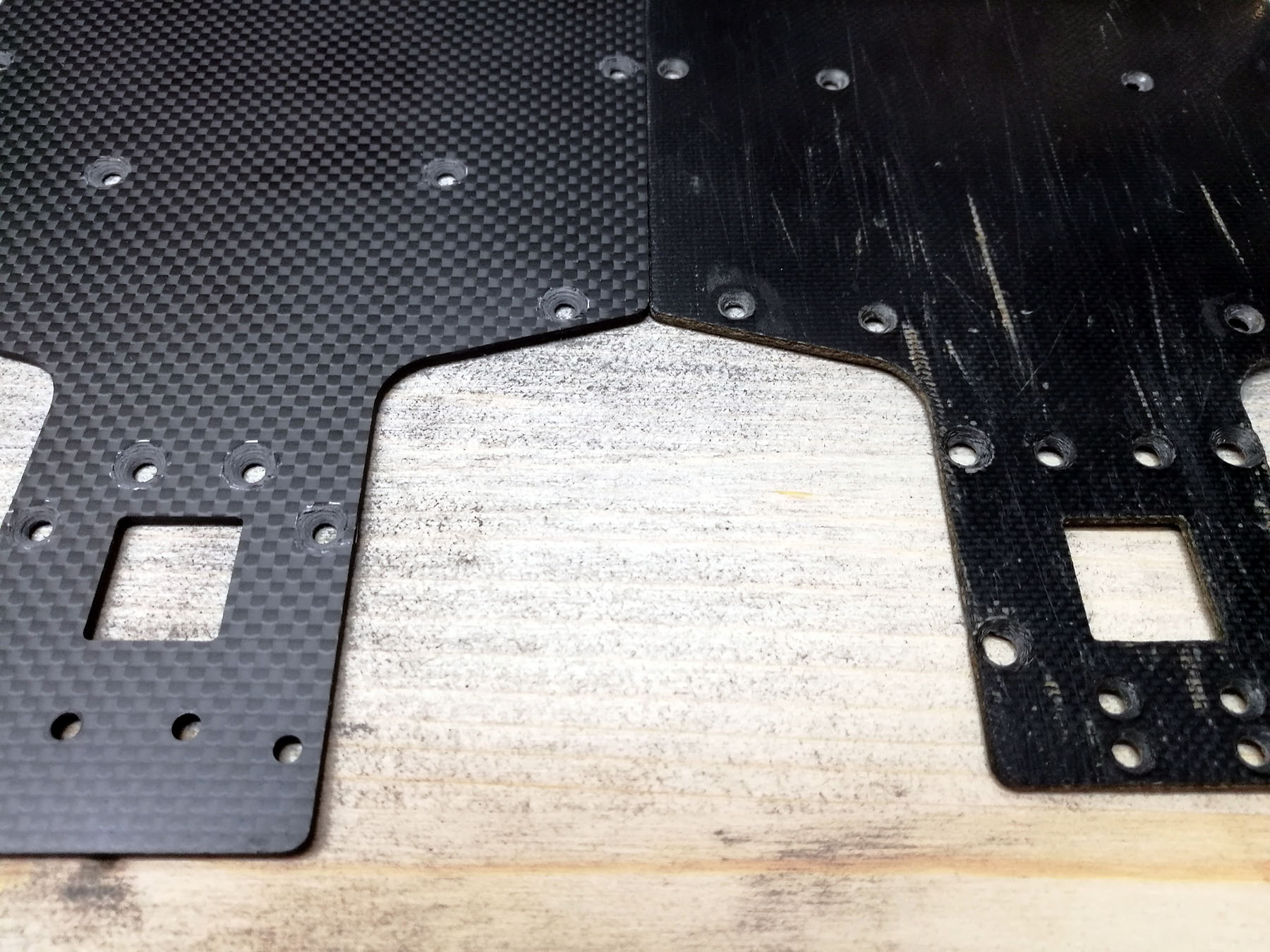

Finishing raw carbon-fiber parts:

200 grit sandpaper to break edges and cleaning out countersunks. Sealing edges and drills with Cyano-glue twice and wait till dry.

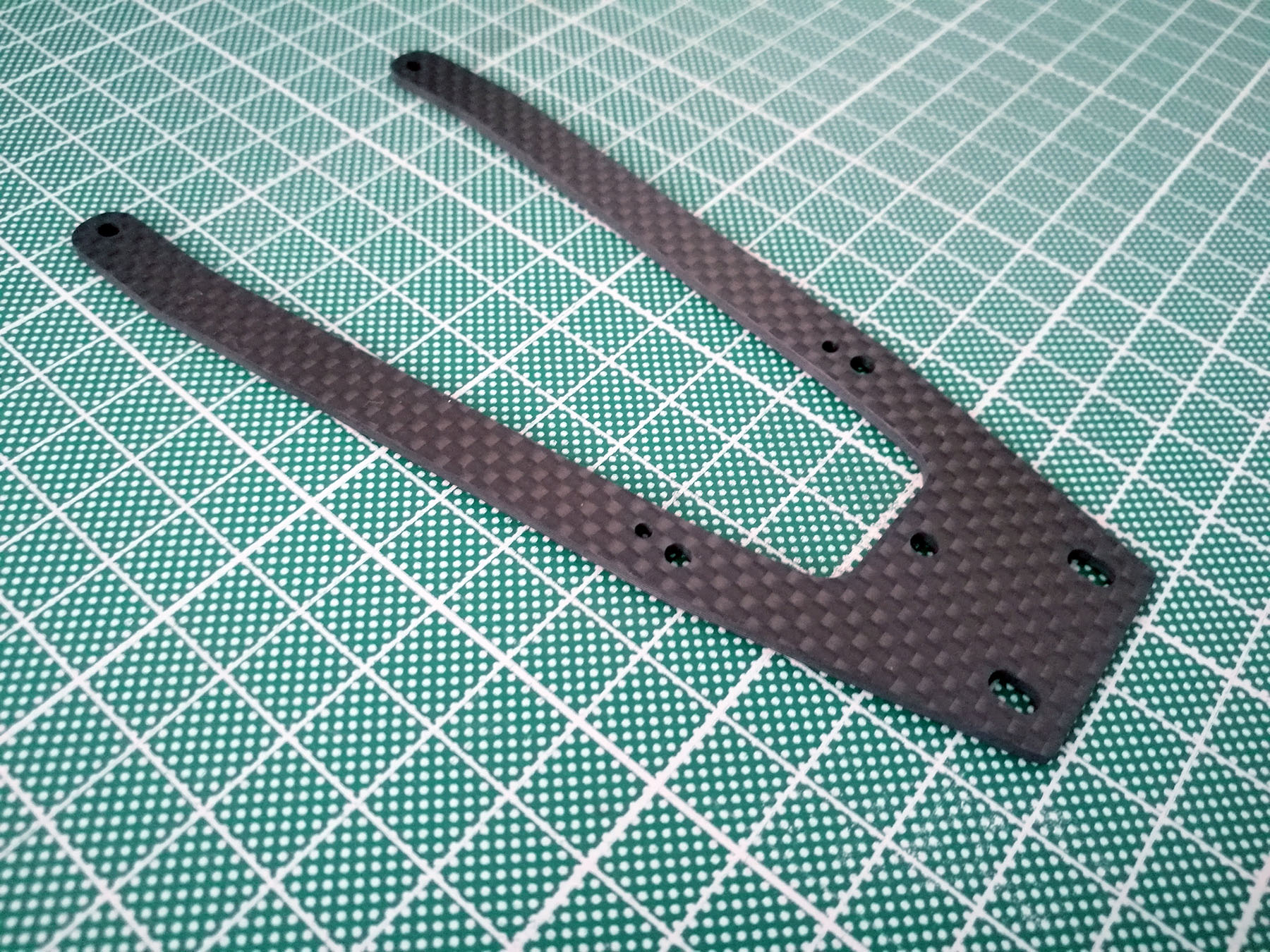

Use a toothpick to disperse the still liquid glue on the edges.

If you do perfect with no drops running away you are done now.

If you do like I do, go furter this way.

Sanding down the edges and surface with a 200 grit sandpaper gently. Again with 400 grit sandpaper (and so on…). Now all over- applied glue is gone and the parts are ready for the built.